When you need reliable pump technology to handle a wide range of liquids, Boerger’s cross-industry pumps can be the solution you seek. From mobile units to submersible and semi-submersible models, rotary lobe pumps to powerful macerators, these systems handle everything from raw water to highly abrasive slurries. And with our Flo-Max team’s engineering know-how, we can customise Boerger pumps to streamline your liquid transfer, processing, and reduction processes.

We are the sole authorised distributor of Boerger Pumps for NSW.

Boerger Pumps for Water, Wastewater & Industrial Fluids

Boerger (Börger GmbH) is a trusted German manufacturer renowned for precision-engineered rotary lobe pumps, submersible pumps and advanced macerating technologies. Their pumps deliver long-lasting performance even in the most demanding water, wastewater, and heavy-industry environments. Their extensive range includes the BLUEline Legend, BLUEline Nova, and ONIXline rotary lobe pumps, the Multicrusher, OrbitGrinder, and Rotorrake macerators, and more.

When combined with our custom engineering, Boerger’s proven designs deliver liquid pumping solutions that not only adapt to your operational needs but also give you distinct advantages and benefits.

Core Design Advantages

All Boerger pumps share the same strengths:

- Self-priming – Each pump can evacuate air and begin pumping without manual priming, simplifying startup and reducing downtime.

- Reversibility – By design, these pumps can easily switch direction of rotation. This easy reverse-running is useful for applications, such as line clearing, clean-in-place (CIP) procedures, or when switching between loading and unloading tasks.

- High resistance to solids and chemicals – All pumps are built with rugged materials and rotor-casing designs that don’t touch, thus minimising wear; ideal for handling abrasive slurries, slops, or aggressive chemical mixtures without clogging or corrosion.

- Short-term dry run capability – These can briefly and safely run dry due to their oil-filled intermediate chambers and robust seal arrangements, which help protect components during short starts or stops.

Boerger MIP®

Boerger pumps are also designed for easy serviceability, thanks to their patented MIP® (Maintenance in Place) standard. This allows all wetted wear parts (rotors, rotor tips, casing liners, shaft seals, etc.) to be inspected, serviced, or replaced without removing the pump from its installation or disconnecting pipework and drives.

This means you can conduct rapid on-site maintenance work at your convenience.

Boerger + Flo-Max custom engineering

With our local engineering expertise, Boerger pumps can also be further custom-configured for your specific application. You can adapt them to Australia’s harsh climate conditions, integrate with existing infrastructure, or enhance performance for challenging fluids.

Benefits of Boerger designs + Flo-Max custom solutions:

- Modular wear-part design for fast, cost-effective replacements

- Easy shaft seal changes without full disassembly

- Quick-release cover for rapid inspection and servicing

- Reduced downtime and maintenance costs

- Extended service life with less disruption to operations

- Local customisation to optimise pump performance for your site and processes

The Boerger Pumps Range: Engineered for Maximum Reliability

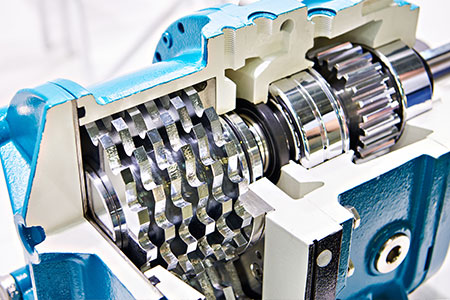

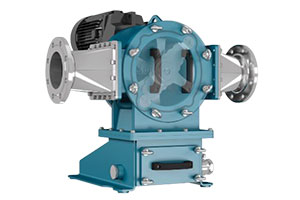

Rotary Lobe Pumps

Boerger’s three Rotary Lobe Pump ranges – BLUEline Legend, BLUEline Nova, and ONIXline – give you the flexibility to handle almost any challenge. With 25 different sizes, capacities from just 1 m³/h right up to 1,440 m³/h, and an extensive choice of fittings and accessories, each pump can be configured to suit your exact operational needs.

BLUEline Legend

This pump features a high-performance yet compact, space-saving design, offering flow rates from 1 to 1,440 m³/h. Known for its stable flow even under increasing pressure.

Main Features:

- Flow rates of 1 to 1,440 m³/h

- 15 pump sizes

- High-performance pumps

- Stable flow rate even with increasing pressures

- Large selection of materials & rotors to suit various applications

- Compact, space-saving design

- Various drive options

- Reversible operation

- Resistant to solids

- Self-priming

BLUEline Nova

For demanding applications requiring both flexibility and efficiency, the Nova can withstand pressures up to 12 bar. The pump can be configured with or without casing protection plates and liners, making it adaptable to specific operational needs.

Main Features:

- Flow rates of 1 to 110 m³/h

- Pressure-resistant up to 12 bar

- With or without casing protection plates and liners

- High volumetric efficiency from optimized rotor-casing fit

- An extensive selection of sealing systems enabled by large seal chamber

- NovaClean for pure, non-abrasive media

- NovaTough for abrasive media containing solids

ONIXline

Boerger’s most advanced rotary lobe pump is designed for high-efficiency operation in demanding conditions. This model is also energy-efficient and nearly pulsation-free, making it ideal for long-term, cost-conscious operation.

Main Features:

- low rates of 1 to 135 m³/h

- Pressure-resistant up to 16 bar

- Almost pulsation-free pumping due to special rotor geometry

- Large area for product-side shaft sealing systems available

- Robust carrier and timing gear combined with precise rotors in a flow-optimized casing ensure the best efficiency even with high pressures

Mobile Pumps

Bring dependable pumping power wherever the job takes you. Designed for quick setup, simple operation, and tough field conditions, these let you operate with confidence and efficiency.

Boerger Mobile Units

These self-contained, ready-to-deploy pump systems are designed for flexible, standalone use in a wide range of field applications. These provide a seamless, single-source solution that combines precision engineering with field-proven reliability.

Main Features:

- High-quality control technology

- Compliance with ATEX and API-676

- Ready-to-connect complete units

- Pump components are wholly designed and built by Boerger

Portable and Handcart Pumps

Here’s a more compact solution for your quick-response pumping needs. Designed for independent operation, these portable units are ideal for situations where mobility and fast deployment are essential.

Main Features:

- Easy to maneuver

- Lightweight for easy transport

- Ready for immediate operation

- Compact design for space-saving installation

- Optimised for simplicity and cost efficiency

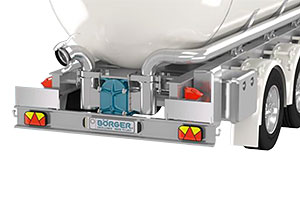

Tanker Truck Pumps

Ensure rapid loading and unloading of tanker vehicles with these pump units. They eliminate the need for complex pipeline layouts and can suit different vehicle setups.

Main Features:

- Quick filling and emptying of the tanker vehicles

- No complicated pipeline layout

- Up to 54% lighter with available aluminium pump configuration without compromising flow rate

- Different attachment options

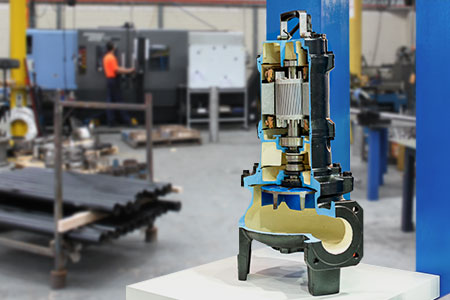

Submersible and Semi-Submersible Pumps

Compact submersible and semi-submersible pumps provide dependable, self-priming performance right inside tanks or pits. They’re the go-to solution when dry installation isn’t possible due to NPSH conditions. Perfect for wastewater treatment and other industrial sites handling viscous and abrasive media in limited or tight spaces.

Submerged Pumps

These liquid pumps are custom-built for each application and specific site. Both the pump and drive are fully submerged in the medium, making them ideal for installations where dry mounting is not possible.

Main Features:

- Installation configuration and lengths according to your specific requirements

- Fully submersible pump and drive

- Guide rods are used to lower and lift the pump

- Riser/pressure pipe conveys medium upwards

- Locking flange holds the pump securely in position with no screw connections needed

Semi-Submerged Pumps

These unites were designed for deep-tank applications. Each pump’s drive is installed outside the pumped medium. This provides easy access for maintenance and protecting sensitive components.

Main Features:

- Individual installation; can be built with a coupling length of 14 m or more

- Assembly plate separates the tank from its surroundings

- Coupling enclosed by coupling guard tube (long shaft connection)

- Riser/pressure pipe conveys medium upwards

- Extension pipe for filling the intermediate chamber and drive

Installation Options

We also offer optional configurations to help you meet site-specific layout and operational requirements. Here are a few examples (click on images for a closer look):

Macerators

These high-performance macerators efficiently break down solids in wastewater and industrial flows, protecting pumps and other downstream equipment. Built for reliability and easy maintenance, they keep operations running smoothly in the toughest conditions.

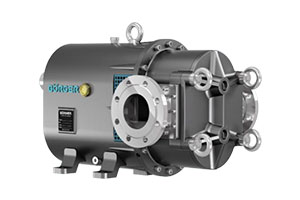

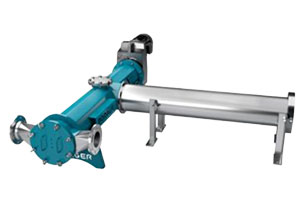

Multicrusher

The Multicrusher delivers high-performance maceration within a minimal footprint. This is a compact and powerful dual-shaft grinder designed for efficient solids reduction in demanding applications. Choose from various blade combinations and adjust the maceration degree to suit specific media and processing needs.

Main Features:

- Dual-shaft grinder

- Capacity up to 320 m³/h

- Available in stainless steel

- Different blade combinations

- Adjustable maceration degree

- Efficient maceration within a compact space

- Easily retrofittable into all systems with minimal installation effort

OrbitGrinder

This cutting basket macerator is designed for precise and consistent solids reduction. It features a constant cutting system that ensures reliable results. Compact and adaptable, the OrbitGrinder can be retrofitted into virtually any system.

Main Features:

- Cutting basket macerator

- Capacity up to 260 m³/h

- Optimal macerating performance and results enabled by the constant cutting system

- Adjustable particle size maceration

- Retrofits into any setup with minimal downtime or installation effort

Rotorrake

A coarse macerator built for high-capacity solids reduction, the Rotorrake is ideal for heavy-duty operations. It features a no-contact blade and counter-blade design that significantly raises its wear resistance.

Main Features:

- Single-shaft coarse macerator

- Capacity up to 540 m³/h

- Available in stainless steel

- No-contact arrangement of blades and counter-blades

- Reversible blades and counter-blades for extended service life

Biogas Processing Solutions

In addition to rotary lobe pumps and macerators, Boerger delivers advanced biogas process equipment that enhances efficiency and maximises output. These systems work seamlessly with Boerger’s core pump technology, completing a robust, end-to-end fluid handling setup.

Bioselect – Achieve precise separation of solids and liquids with an efficient unit that delivers a high dry matter content for optimal downstream performance.

Powerfeed – Maximise your biogas yield with this robust system that continuously and evenly feeds substrates into digesters for smoother, more consistent operation.

Agitator – Ensure uniform mixing with a durable and energy-efficient solution that homogenises liquid media with solids to maintain ideal processing conditions.

Stainless Steel Tank – Safely store, digest, or mix liquids with a corrosion-resistant tank built to handle a wide range of biogas applications.

A Wide Range of Applications

Industrial:

- Chemical

- Paint & Lacquer

- Adhesive & Resin

- Mining

- Oil & Gas

- Petrochemical

- Pulp & Paper

- Pharmaceutical

Environmental:

- Water & Wastewater

- Tank Drainage

- Sewage & Sludge

- Disposal & Recycling

- Membrane Filtration

- Vacuum Dewatering

Marine & Offshore:

- Oil-Water Mixture

- Bilge

- Ballast Water

- Oil Recovery Vessel

- Skimmer Pump

- Food Waste

Disaster Relief:

- Flood Control

- Coastal Protection

- Foam Extinguishing

- Fire-Fighting

- Hazardous Material Pump

Food:

- Sugar Refinery

- Starch

- Magma & Molasses

- Crystal Slurry

- Yeast

- Wine & Distillery

Agriculture & Biogas:

- Liquid Manure

- Vat Filling Station

- Nutrient Management

- Silages

- Biogas Plant

- Renewable Resources

Flo-Max’s Comprehensive Technical Support

At Flo-Max, we know your operation demands reliable and efficient pumping, without interruptions.

That’s why our engineering team provides full technical support from installation to long-term maintenance. We’re highly familiar with Boerger pump technology and can help you maximise performance, extend service life, and adapt systems as your needs evolve. From preventive maintenance and repairs to custom modifications, we work to keep your processes running smoothly.

Achieve consistent flow control without compromise

From wastewater and mining to food processing and chemical handling, Boerger pumps deliver dependable performance in demanding environments. Wherever you are in Australia, we can advise you on model suitability, provide technical details, offer a price quote, or arrange a demonstration.