Production scale freeze dryers are vital to numerous manufacturing processes. These machines can preserve a wide variety of materials in huge quantities. Whether it’s mass-preserving food, creating cosmetics or developing pharmaceuticals, these big commercial freeze dryers allow you to scale up your production, safely and efficiently. With the right freeze-dryer technology, you can grow your business and pursue bigger opportunities.

If you’re seeking to enhance your operations, we are here to help. We have the large-scale industrial freeze dryers and technical expertise to make your enterprise thrive.

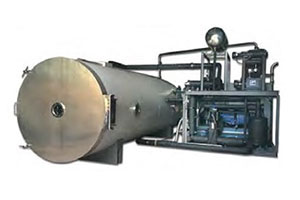

Flo-Max Large Production Scale Freeze Dryers

Our Industrial Freeze Dryers efficiently lyophilise quantities of materials ranging from 10kg to 2,500kg. Our comprehensive range of machines can safely cater to diverse applications and are also food-safe.

We can also modify these industrial freeze dryers according to your specifications. You can consult our engineers and get installation assistance with modified models.

General Features

- Partitioned pre-freezing function available

- Reduced-noise compressors ensure both efficiency and stability

- Offers high pumping speed

- User-friendly touchscreen provides an easy, intuitive interface

- Dry chamber is sealed off by a leak-proof aerospace-grade high-strength acrylic door

- Nitrogen- or inert gas-ready chamber for the post-drying process

Available Models

Premium Production Scale Industrial Freeze Dryer. Our largest units can handle as much as 2,000 kg of material and are food-safe. These are the industry standard for the large-scale preservation of food ingredients or pharmaceuticals.

FD500. The next largest unit has a chamber that houses multiple drying shelves totaling an area of 50 square metres and a maximum load capacity of 500 kg.

FD200/300. These models can handle 200 – 300 kg of material. Like the larger freeze dryers, it can achieve a cold trap temperature of -65 degrees Celsius.

FDS50/100. Our mid-range industrial freeze dryers have all the same features as our larger models, but with a smaller footprint. Best used for loads between 50 to 100 kg.

FDB20. This is the smallest model among our water-cooled freeze dryers. Handles a maximum load of 20 kg and can also achieve -75 degree Celsius during lyophilisation.

FDB10. These movable standing freeze dryers lyophilise with cooled air instead of water. With 10 kg capacity and a cold trap temperature of -50 degrees Celsius, they’re perfectly matched to the needs of small enterprises in food or organic cosmetics.

Applications

- Agriculture, retail food products and food services. Food preservation (e.g., fresh produce, prepared dishes or drinks, pet food) and nutrition retention are often best achieved through freeze-drying.

- Pharmaceuticals production. Lyophilisation is a requirement in the manufacture and/or preservation of many key components of vaccines, medicines, hormones, vitamins and nutritional supplements.

- Biochemical production. Commercial freeze dryers are a critical part of creating and preserving various biochemical compounds (e.g., enzymes and other proteins, antitoxins)

- Transport and trade. Many perishable goods (e.g., imported tropical fruits and herbs) are freeze-dried to reduce their weight and volume — thereby reducing the cost of storage, transport and distribution anywhere in the world.

- Military rations and emergency supplies. Companies that mass-produce ready-to-use meals and other space-saving essentials for government emergency preparedness departments, international relief organisations, military forces, space travel agencies, science expeditions and extreme outdoor athletes, rely on freeze-drying technology.

- Frequent sample preservation. Maintaining organic tissues through freeze-drying for medical, forensic or other research work is essential to achieving accurate findings.

- Routine archaeological or museum artefact preservation. Some large universities and museums may even require a shared facility where they can freeze-dry precious historical treasures (e.g., medieval documents; prehistoric midden heap scraps).

The Benefits of Using Flo-Max Industrial Freeze Dryers

After four decades of dealing with freeze-drying technology, we know how important engineering efficiency is to growing businesses like yours.

We use all our expertise and experience to design our freeze dryers, especially for mass production. So whether you’re dealing with food, pharmaceuticals or scientific research, our large-scale freeze dryers will provide you with the following benefits:

- Production Flexibility. Our freeze dryers offer flexibility in production. These can equipped to handle lyophilisation for a wide range of materials and quantities, both for current and planned product lines. This makes them nearly future-proof.

- Low Investment Risk. Flo-Max large production scale freeze dryers are durable, adaptable and scalable. So you can start with the minimum number of units needed and then install more to deal with increased production demands as your business grows.

- Better Product Quality Control. Biodegradable or biological materials that have been properly lyophilised with a Flo-Max commercial freeze dryer maintain their integrity much longer. You’ll have full control over any finished products you create with them.

- Better Production Cost Control & Redundancy. Flo-Max offers you different commercial freeze-dryer models of various capacities, plus the technical expertise to integrate these into your production line. You’ll be able to retool your production process to minimise costs and build in fail-safes and redundancies to minimise failures.

- Ease of Use. Flo-Max designs its commercial freeze dryers to have user-friendly control screens. You won’t need to hire an expert to run them.

- Quick Implementation. Flo-Max’s expert engineers can custom-install your chosen commercial freeze dryers according to your needs. After a month of testing, you and your team will be up and running.

- Quick Technical Support. Plus, you’ll have Flo-Max’s engineering and technical support to back you up. Our people are some of the best pump engineering experts in the world, all within easy reach.

Ready to unlock the full potential of your freeze drying production runs?

Let Flo-Max technology take your freeze-drying operations to the next level. No matter where you are in Australia, feel free to contact us today to get more technical details, a price quote or a unit demonstration. With decades of experience, we’ll help you find the optimum freeze dryer machine for your particular commercial needs.