We value side channel blowers for being durable, reliable, and their ability to provide consistent performance across various applications. In industries where cost efficiency is paramount, these pumps are known for their versatility and low maintenance needs. To illustrate this, here is an overview of the wide range of applications of side channel blowers.

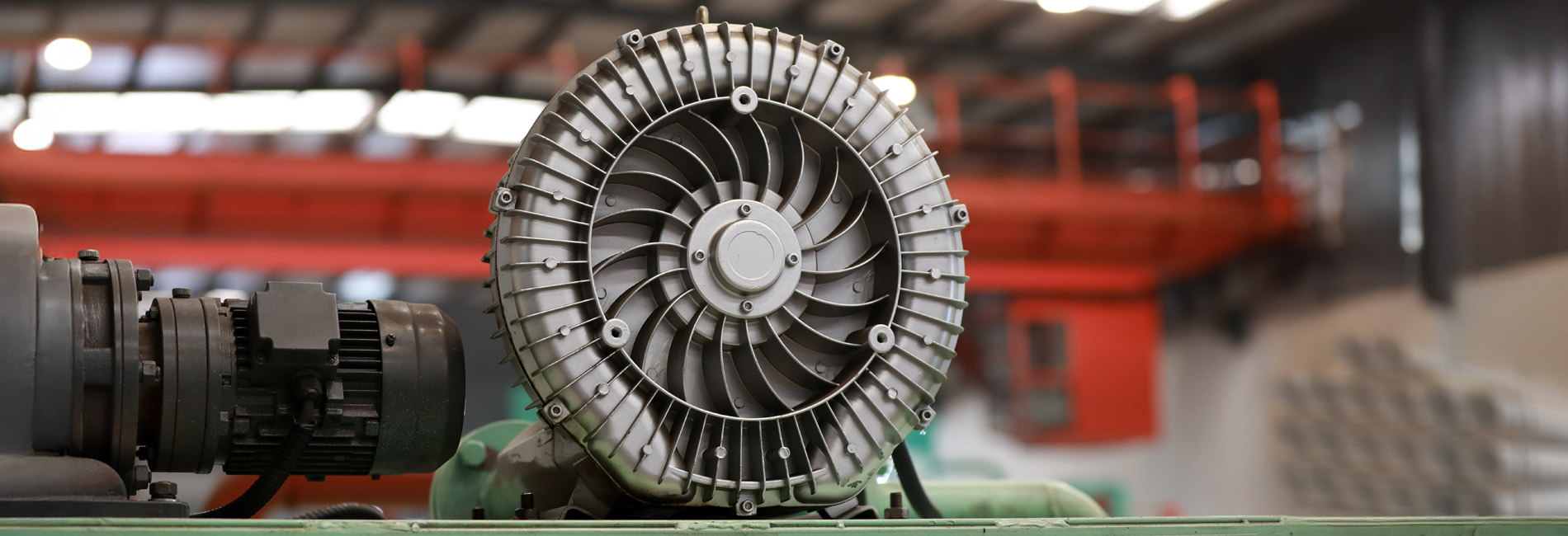

How Side Channel Blowers Work

Side channel blowers operate on the principle of regenerative flow. Air is drawn into the blower and repeatedly accelerated by impellers along a spiralling channel, creating high pressure and vacuum.

Unlike centrifugal or axial blowers, they rely on this regenerative mechanism to achieve higher pressures without requiring multiple stages or complex configurations.

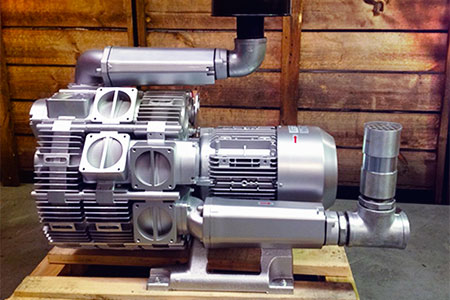

Compared to other air-moving technologies, side channel blowers stand out for their ability to deliver high pressure and vacuum levels with minimal maintenance.

Key Features

- High Pressure and Vacuum Capabilities: Ideal for applications needing precise airflow control.

- Oil-Free, No-Contact Operation: Ensures clean air delivery, crucial for sensitive environments.

- Low Maintenance: Simplified design reduces mechanical wear and tear.

How Side Channel Blowers Are Typically Used

Because of their efficiency in handling air and gas conveyance, side channel blowers are a critical component for the applications listed below. If any of these are the processes you manage, these blowers are the correct pump technology to use.

Aeration in Wastewater Treatment

Side channel blowers are widely used to oxygenate water in treatment plants. They are crucial in supporting the growth of aerobic bacteria that break down organic waste.

Pneumatic Conveying Systems

These blowers efficiently move powdered or granular materials through pipelines, common in industries such as food processing, pharmaceuticals, and plastics.

For food processing, cosmetics and pharmaceuticals in particular, the dangers posed by contamination are high. This is where the clean and pulsation-free operation of side channel blowers becomes indispensable.

Vacuum Lifting and Handling

In manufacturing, side channel blowers enable the lifting and transportation of objects using vacuum suction, minimising the need for manual handling. Similarly, packaging industries employ these blowers to manage lightweight materials efficiently and without damage.

Aquaculture

Fish or aquaculture farms use side channel blowers to aerate large water bodies. This ensures oxygen levels are sufficient to support healthy life in tanks, manmade ponds, and remediated aquatic ecosystems.

Side Channel Blower Versatility and Specialisation

If you’re in a more specialised industry, you may consider using side channel blowers as well. These are versatile enough to be scaled up or down and modified, for highly specific applications. Here are a few examples:

- Medical and Dental Equipment – Side channel blowers are sometimes employed in surgical suction devices and dental vacuum systems, where reliability and cleanliness are critical.

- Vacuum Packaging – Food preservation systems employ these blowers to remove air from packaging, extending product shelf life.

- Wind Tunnel Testing – In research and development, side channel blowers simulate airflow in small-scale wind tunnels for product and safety testing.

- Precision Cutting – When cutting materials like wood, glass, aluminium, steel or plastic into precise shapes, manufacturers sometimes rely on side channel blowers. These create the clamping pressure that holds the material safely in place, as a CNC router (a computer-guided machine) makes the precision cuts.

- Grain Winnowing and Preservation – In Asian countries where rice is a staple, these blowers are an important component of rice polishing machines, aiding in the separation of husks. Meanwhile, agricultural sectors in countries that grow and export wheat use side channel blowers to keep wheat grain dry and aerated during silo storage.

- Beer Brewing and Wine Production – In Germany, France, Italy, and other European countries, these blowers find applications in beer breweries and wineries. Side channel blowers aerate beer yeast cultures or squeeze wine grapes to extract their liquid.

- Aerospace Engineering – Aerospace agencies like NASA incorporate special side channel blowers in the ventilation systems of astronauts’ EVA suits.

What to Consider Before Choosing A Side Channel Blower Model

Are side channel blowers the better option or replacement for a different pump type in your operations? Is it the only technology that suits your particular process? Which model or make is best for operational and cost efficiency? Find out in our related article that covers choosing the right side channel blower for your requirements.

Click the following link to view our side channel blowers product list.

Conclusion: Are Side Channel Blowers Right for You?

Side channel blowers are often the more sensible option in many applications. They have come a long way since their invention, evolving into essential tools for various industries. From wastewater treatment to wind tunnel testing, their unique design and functionality enables them to excel in diverse environments. And as technology advances, we can expect further improvements in their efficiency, noise control, and adaptability. You can be confident that side channel blowers will remain relevant in the future.

For more information, feel free to explore our full range of air control pumps or contact our air control experts.