Side channel blowers come in several possible configurations. How do you choose the right side channel blower model for your process?

The answer lies in understanding this pump technology’s unique advantages and how well they align with your specific application. Evaluate your needs carefully before deciding which models will best optimise your operations and maximise efficiency.

Where Side Channel Blowers Excel

Before you choose a side channel blower model, remember where this pump type works best.

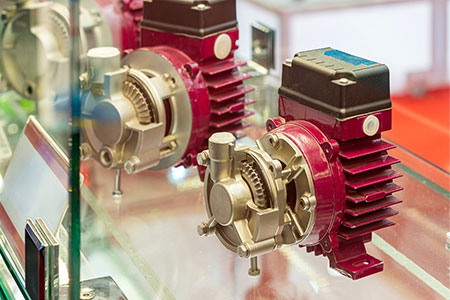

Side channel blowers are notable for achieving high pressure and vacuum levels with low maintenance requirements. These blowers repeatedly accelerate the air they draw in with impellers within a spiral-shaped channel. This enables them to generate the necessary pressure or vacuum for specific applications.

Key Features

Side channel blowers have 3 features with distinct advantages:

- Simple Design with High Pressure or Vacuum Capabilities. Side channel blowers achieve higher pressures or vacuums without requiring extremely complex configurations. These blowers are best for stable flow, low to medium steady pressure applications (up to 1,000 mbar) that need precision air control. (They may be less efficient in handling wildly fluctuating loads or extreme pressure demands.)

- No Contact, Oil-Free Operation. There is no contact between moving parts, reducing contamination or the need for mechanical lubricants. Because they’re designed for no-contact, oil-free operation, side channel blowers can ensure clean airflow delivery. This is especially crucial in industries where contamination of operating environments could have severe consequences on product quality and safety.

- Low Maintenance. Their contact-free design also reduces mechanical wear and tear, almost eliminating the need for regular maintenance. This means you can run operations continuously without the frequent maintenance required by other types of blowers. This helps reduce your downtime.

Most Common Applications

While the list of side channel blower applications is long due to their versatility, they are most often used in these areas:

- Wastewater Aeration – aerating water to support beneficial flora and fauna to break down organic waste

- Sanitised Pneumatic Conveyance – moving powders or granular products through pipelines, without outside contamination

- Vacuum Lifting – for general manufacturing processes that involve lifting and transportation of lightweight objects or packages without damage

- Aquaculture – oxygenating tanks, ponds and remediated ecosystems to support healthier aquatic life

Do A Comparative Analysis of Applicable Pump Types

Are side channel blowers the only technology that suits your particular process? Or are these an alternative to a different but equally applicable air pump type? To answer this, experienced pump engineers can help you do side channel blower efficiency tests and comparative analyses with alternative pump types.

To illustrate, here are two summary examples of how such comparisons might go for specific industries.

Example Assessment 1: Agricultural Composting Aeration Systems

- Side channel blowers are well-suited for aeration systems in composting because they deliver steady and oil-free air. Their energy use is moderate, as they are designed for continuous operation without requiring frequent maintenance. They are particularly cost-effective for medium-scale composting facilities where consistent and moderate pressure is sufficient.

- Axial fans are typically more energy-efficient for low-pressure, high-volume applications, especially in open compost piles. However, their ability to create pressure is limited, which might compromise airflow consistency in more compact or dense composting systems. Initial costs are often lower, but they may require supplementary equipment to achieve the same results as side channel blowers.

- Centrifugal fans can provide higher pressure and greater airflow precision, making them suitable for enclosed systems. However, they tend to consume more energy than side channel blowers at similar output levels, especially in continuous operations. Maintenance requirements may also increase due to more complex moving parts.

Verdict: For agricultural composting aeration, side channel blowers strike a balance between cost and performance, especially in systems that require medium pressure and consistent airflow without interruptions.

Example Assessment 2: Industrial Dust and Fume Extraction

- In dust and fume extraction systems, side channel blowers excel due to their oil-free, contactless operation and ability to run continuously without significant wear. They are energy-efficient for medium-pressure demands and offer lower long-term maintenance costs compared to some alternatives.

- Meanwhile, centrifugal blowers are better suited to high-volume airflows in open spaces. However, they may consume more energy at medium pressures due to their design. Additionally, their higher initial cost and more frequent maintenance can make them less cost-effective over time for medium-duty extraction systems.

- Industrial vacuum pumps provide high suction power and are excellent for localized dust extraction. However, they are far less energy-efficient for large-scale or continuous operations. Their smaller capacity and need for regular filter maintenance increase operational costs significantly compared to side channel blowers.

Verdict: Side channel blowers are a cost-effective solution if you are running medium-duty, large-area extraction systems. For localized or heavy-duty extraction, industrial vacuums may perform better but with higher costs.

What to Consider When Choosing A Side Channel Blower Model

Once you’ve decided this technology is your best option, use the following link to view our full range of industrial side channel blowers.

How do you choose which side channel blower model is best? Here are the main factors you should assess before making that decision.

1. Load Conditions

What type of operation are you conducting? What are your maximum and minimum flow rate and pressure requirements? Ensure your chosen blower model meets your specific operational demands. If a side channel blower is overloaded it will increase your overall energy consumption.

2. Space and Physical Integration Needs

How much operating space do you have for your systems or machinery? Do you need more compact designs to deal with limited space? What are the limits on overall noise levels in your work environment and will you need noise-reduction features?

3. Blower Design

A blower’s design determines how much energy is conserved or lost during operation. What size is it? What kind of materials make up a particular blower model (e.g., stainless steel), and do these reduce friction during operation?

4. Latest Technological Advancements

Side channel blower technology dates back to the early 20th century. However, as environmentally sustainable and energy-conscious solutions become ever more important, innovations and refinements will continue. These impact how side channel blowers can be optimised for a wider range of industrial applications – and thus, which model you choose to future-proof your system. For instance:

- Noise Reduction – Early blower models were bulky and noisy, but advancements in materials and design have led to compact, quieter systems. Modern side channel blowers now have noise-dampening features, such as optimised impeller designs and soundproof casings. Future models might even be suitable for environments where noise levels are minimised down to nearly 0 dB.

- Motor Efficiency – Innovations in motor technology, including variable frequency drives (VFDs), have significantly improved energy efficiency, reducing operational costs.

- Smart Controls – Future models may incorporate IoT-enabled sensors to monitor performance, predict maintenance needs, and optimise energy use in real time.

- Material Innovations – Research is underway to use new lightweight, corrosion-resistant materials, expanding their use in harsher environments, such as chemical processing or deep ocean applications.

The best way to keep abreast with advancements in pump engineering is to regularly consult a pump OEM with a team of engineers who specialise in creating pumps for your industry.

5. Energy Consumption

A side channel blower’s motor also determines how efficient it is at using energy. What kind of motor will be driving a particular model? How much electricity will it require? How long and how often will the blower be in operation? When a good blower design is paired with an energy-efficient motor, you are more likely to reduce your energy consumption and minimise your carbon footprint.

6. Maintenance

Regular upkeep, including cleaning and part replacement, ensures that side channel blowers operate at peak efficiency. Given that these blowers are generally meant to be low-maintenance, how much (or how little) maintenance does a particular model realistically require? Will it suit your current manpower and resources?

The point of this assessment is to determine side channel blower efficiency, in relation to your current system workload. Your goal in choosing the side channel blower model is to prevent your overall operating costs from escalating.

We can help you choose the right side channel blower technology

Side channel blowers are recognized for their high efficiency. However, their actual energy performance can fluctuate based on the specific requirements and conditions of the application. They are an excellent choice for applications demanding medium pressure, clean airflow, and continuous operation with minimal maintenance. Their efficiency and versatility make them a compelling option for businesses seeking reliable, long-term solutions.

If you need guidance on how to choose the right side channel blower model, we’re here to help. We specialise in helping businesses like yours build the right pumping systems that optimise your processes. We can help you adapt and make the most of the latest pump engineering available.

Contact us today to explore how our full pump product range and services can transform your operations.