Reliable Performance for Heavy Industries – Selected, designed and supported by real engineers

Why Choose Flo-Max For Progressive Cavity Pump Installations?

At Flo-Max, we understand the challenges you face in your industry. Since 2001, we have helped clients like yourself integrate progressive cavity pumps with other pumps-based operations. We can meet your specific needs.

Pump Engineering Expertise

Our team members have decades of experience and can tap into our network of partners throughout Australia’s pump engineering industry. We can provide you with the experts who can help you leverage the advantages that progressive cavity pumps bring and navigate their limitations. We’ll ensure seamless integration with your existing operating systems.

Comprehensive Service

When you choose Flo-Max, you gain more than just access to advanced technology. You will have dedicated technical support throughout the entire process—from installation to testing and validation. You’ll be guided and given expert advice on maintenance and repairs to ensure your operations run smoothly.

Optimised Productivity

Our goal is to enhance your productivity while keeping operating costs manageable. We tirelessly pursue the best solutions to ensure your pump technology performs at its peak.

Experience the difference with Flo-Max—where expertise meets exceptional service.

High-Performance Progressive Cavity Pumps

We offer only the most durable progressive cavity pump designs from our most reliable manufacturers, including SEEPEX GmbH. These pumps handle a wide range of fluids with various viscosities and textures. That includes difficult mixed media with randomly sized solids, liquids, gases, corrosives and abrasives. Even at high pressures, these pumps can convey or apply liquids or materials into any channel or container, precisely and safely.

General Features

- Versatile technology; has flexible installation options (e.g., rotor or stator geometries, rotation and flow)

- Can be operated vertically or horizontally (depending on the pump model)

- Low pulsation; excellent for maintaining continuous uniform flows and pressures

- Suitable for various difficult liquids, oils, slurries or other mixed materials with low or high viscosity

- Applicable also to fluids that are air-entrained, multiple-phase, corrosive or abrasive

- Capable of precision dosing (for specific progressive cavity pump models)

- Self-priming and valve-less

- High suction capacity

- Also makes an accurate metering pump

Industrial applications

Progressive cavity pumps are easily adapted to many industries, such as:

- Chemical and biochemical manufacturing

- Mining

- Agriculture (e.g., irrigation, sugar refining)

- Ceramics

- Textile dyes

- Construction (e.g., cement conveyance, packaging adhesives)

- Food and beverage

- Oil and natural gas

- Cosmetics

- Pharmaceuticals

- Wastewater treatment and water management

- Floodwater management

- Paper production

Product Range

What do you need for your business operations? Browse through the different types of progressive cavity pumps we offer.

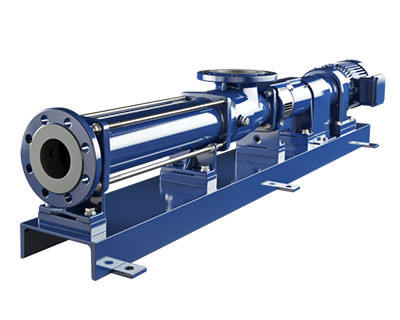

Standard Progressive Cavity Pumps

These form the basis of various modular pump systems. Featuring an API 676 standard pump that can handle liquid, oil and gas applications, these deliver anywhere from 48 to 96 bar pressure and have a conveying capacity of 0.01 to 500 m³/hour. You can select different rotor and stator geometries and have them installed according to your requirements.

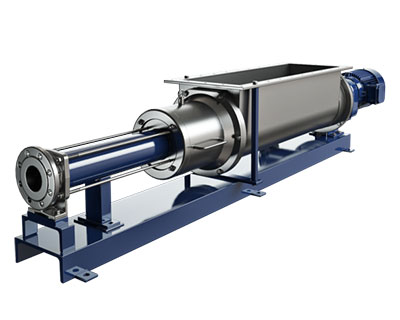

Open Hopper Pumps

Open hopper pumps are designed to handle highly viscous and semi-solid materials with low flowability. They make excellent pumps for processing freshly harvested produce and agricultural by-products, as well as dewatering sludges or conducting wastewater treatment.

Choose from 10 hopper pump lines that offer a conveying capacity range from 0.25 or 130 m³/hour. You can also select the right size and pitch for the feed hopper and auger feed screw to suit your particular application.

Precision Metering Pumps

Progressive cavity pumps make excellent metering pumps, achieving high accuracy (+/- 1% deviation). They provide constant low-pulsation flow (0.2 to 1,000 L/H, 0.053 to 264 USGPH) independent of any pressure and are especially useful for monitoring sensitive media.

These metering pumps are also highly customisable. There’s a wide range of modular components and material options to choose from and you can have larger multiple-drive combinations, vertically or horizontally mounted.

Hygienic Food Pumps

Whether you’re manufacturing beverages, fruit pulp, creams, pastes, syrups or other products for human or animal consumption, we have the food-safe pumps to help you fulfil your most stringent sanitary requirements. These have a conveying capacity range of 30 L/H to 130 m³/hour or 0.132 to 572 USGPM.

The food-safe pumps we offer are easy to clean, have relatively low space requirements and feature built-in residue cleaning and sterilisation processes. More importantly, they comply with EHEDG principles and American 3-A Sanitary Standards. The materials used for contact components also fulfil the requirements of both the EU 1935-2004 and the FDA (USA).

Wobble Pumps

Unlike other progressive cavity pumps, wobble pumps operate with rotating units that have only one joint. The flexible stator “wobbles” to efficiently convey thin to moderate viscosity liquids at up to 10 m3/hour or 44 USGPM. This simple engineering design (with the drive flanged directly onto the pump) leads to a shorter, more compact footprint and easier, lower-cost operations and maintenance. Because of their simplicity, wobble pumps can be used in a wide range of applications and industries.

Semi-submersible and Fully Submersible Pumps

These pumps are designed to drain liquids or other media from any container, basin or catchment. Depending on your chosen model, these can be partially or fully immersed at various depths. They can handle corrosive or abrasive matter, from low to high viscosity, and are capable of conveying them at 30 L/H to 300 m³/hour or 0.132 to 1,320 USGPM. They are also a space-saving and cost-effective alternative to other pumping systems, especially in situations involving critical suction heads or limited installation space.

Mining Pumps

Heavy-duty mining operations require durable pump systems for high pressures and fast flows. The models we offer feature equal wall stators that let you convey highly variable fluids and sludges while dealing with pressures as high as 240 M and flows up to 100 m³/hour.

We also have robust, compact mine dewatering units. These can separate solids from mine water and be quickly retrofitted into existing dewatering systems. You can also get customised versions of the central pump and settling tank, to adapt to the range of flows and pressures typical of your operations.

Smart Air Injection Pump System

If you need to transport liquids, slurries or mixed materials over longer distances (up to 1,000 metres) and with radical changes in direction and height, this is the solution for you. This custom-built pump system combines progressive cavity pumps with compressed air technology. It gives you efficient control over conveyance while running on just 72% of the energy consumed by more conventional pumping methods. It also has automated operation and maintenance features that make replacing the pump rotor and stator (when needed) easier.

Macerators

Progressive cavity pump-macerators are built to shred solid, coarse or fibrous components at flow rates of 2 to 150 m³/hour. When installed, these reduce the hazards to other pumps and downstream components in your plant’s system.

Easy to maintain, reliable, energy-efficient and with flexible installation options (e.g., shear plate design, vertical or lateral intake), these macerators are perfect for enhancing safety in industrial wastewater and public water management,

Boost Your Operations’ Productivity and Safety

Ready to elevate your operations? Our expert engineers are here to guide you. Contact us today for tailored advice, detailed technical information, and a competitive price quote on the perfect progressive cavity pump for your needs. We’ll also advise you on other pump engineering technologies you need. Make the smart choice for enhanced productivity and safety with Flo-Max.