For heavy-duty industrial operations, we can provide you with the best cutting-edge pump engineering solutions.

Engineered Pumping Categories

Consult our engineers for help in choosing the right set of large-volume pumps for you.

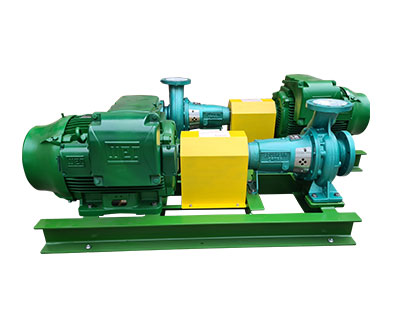

Centrifugal Pumps

We have high-performance centrifugal pumps in various sizes, for every solid or liquid application. These include end suction pumps, multi-stage pumps, self-priming pumps, magnetic drive pumps, borehole pumps, and more. These units can handle the toughest and most

demanding of environments and quantities. We proudly carry and support Australian pump brands like Southern Cross, as well as pump technology by respected global companies such as Grundfos, Sulzer and Victor Pumps.

Available configurations

- Vertical-mounted

- Base-mounted electric-driven

- Frame-mounted

- Close-coupled

- SAE-mounted, engine-driven

- Engine-driven packages (trailer or skid)

- Sound-attenuated packages (trailer or skid)

Applications include

- Water supply management

- Fire protection systems

- Sewage/slurry disposal and sump management

- Food and beverage manufacturing

- Chemicals manufacturing

- Industrial oil and gas operations

Split Case Pumps

We also have a wide range of axially split pumps, in various sizes. These are designed for specific industry applications, such as carbon dioxide injection, cooling water, and boiler feedwater

management.

Available configurations

- Single, double, and multi-stage designs

- Vertical, horizontal, and double suction versions

Applications include

- Processing liquids

- Liquid transfer

- Offshore seawater management

- FPSO offloading

- Closed cycle cooling

- Tank farm boosting

- Water supply and irrigation

- Booster pumps for pipelines

- FPSO seawater lift applications

Sump Pumps

We have the drainage or sump pumps to meet the challenge of proper sump management. Our models are robust and represent the best of pump engineering in Australia, as well as from other global manufacturers (such as Tsurumi Pumps). They are made of materials (e.g., thermoplastic material, fibreglass) that are highly resistant to chemicals and corrosive agents present in various types of wastewater. They can handle a large range of temperatures without any damage to submerged casings.

Available configurations

- Process sump pumps

- Vertical centrifugal sump pumps

Applications include

- Wastewater treatment

- Drainage

- Floodwater diversion

Submersible Sewage Pumps

We can provide you with fully submersible sewage pumps to handle mixed liquids with suspended solids, without clogging. These pump designs are from reliable manufacturers (such as Tsurumi Pumps) and are ideal for raw sewage and wastewater. Some are equipped with wider passages and de-clogging features such as vortex or cutter impellers for shredding solid or fibrous matter. All pump models are explosion-proof and can ensure smooth and efficient operations even in hazardous conditions.

Available configurations

- Chopper pumps

- Vortex impeller pumps

- Grinder pumps

- High head / high pressure delivery pumps

- Open channel

Applications include

- Municipal sewage treatment

- Industrial wastewater management

Air-Operated Plunger Pumps

These are cylindrical, hollow piston-based pumps that can provide a controlled and metered flow. Air pressure powers the pump as it compresses liquids, which flow through the piston and into the discharge side of the cylinder. No actual air or power source comes in direct contact with the liquids. These can pump any fluid or semi-solids, including hot, foamy or viscous ones, at any angle.

Applications include

- Soft wash operations

- Portable sanitation

- Disinfection

- Agricultural pest control

Air-Powered Diaphragm Pumps

Our range includes portable single diaphragm, tubular diaphragm, and air-operated double-diaphragm (AODD) air-powered units. These can suit a wide range of applications, small to heavy-duty, from simple sludge or waste sump management to pumping large amounts of hazardous liquids. We have diaphragm pumps in stainless steel, aluminium, polypropylene, or other materials that are corrosion- and leak-resistant.

Industrial applications include

- Water and waste treatment

- Chemical industry

- Automotive parts production and assembly

- Textiles

- Leather tanning

- Electroplating ceramics

- Ink and paints

- Paper production

- Construction

- Water and Waste treatment

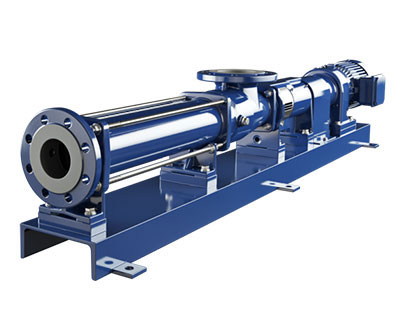

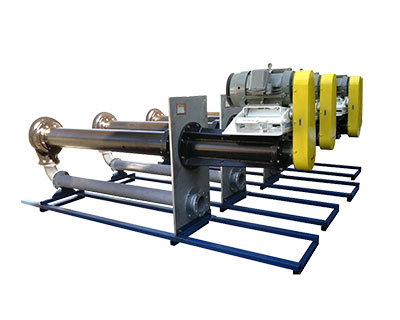

Progressive Cavity Pumps

We have the progressive cavity pumps to channel or redirect fluids, slurries and challenging mixed media of various textures and viscosities. Browse through the most durable pumps from our trusted manufacturers.

Applications include

- Oil and natural gas

- Mining

- Agriculture (e.g., irrigation, sugar refining)

- Ceramics

- Textile dyes

- Construction (e.g., cement conveyance, packaging adhesives)

- Food and beverage

- Cosmetics and pharmaceuticals

Agilent Vacuum Technologies

We offer Agilent’s cutting-edge vacuum pumps, measurement instruments, replacement components and accessories for high-tech, high-precision operations.

Applications include

- Electronics manufacturing – vacuum coating and metallurgy

- Liquefied natural gas transportation

- Manufacture of scientific analytical instruments (e.g., particle accelerators, mass spectrometers)

- Nanotechnology

- Gas leak detection

- Medical research

Laboratory Equipment

We offer disintegrators and other laboratory equipment essential for processing solids in various industries like agriculture, food & beverage, and scientific research. Our disintegrators effectively process materials like grains, plant matter, soil, minerals and medicines into finer particles, and different capacities and speeds. These can also work as part of a larger pump-based production system.

Applications include

- Medical services and laboratory research

- Cosmetics and pharmaceuticals

- Food and beverage

- Agriculture

- Waste processing