Over the coming years, more communities and businesses will need to make water recycling in Australia a priority. We must secure sustainable supplies and strengthen climate resilience.

If you’re an Australian developer, council officer, asset owner, or community leader searching for real-world models of water resilience, you don’t have to look far. Across the country, you’ll find good examples of planned water reuse and recycling systems. These help keep towns, industries, and public spaces running efficiently, even during drought.

This article gives non-technical project managers a quick walkthrough of the most common water reuse and water recycling models in Australia, along with successful cases to inspire you. You’ll have a clear overview of how they work, what pump technologies keep them operating, and what lessons you can apply to your own project.

Main Planned Water Reuse & Recycling Models in Australia

Below are the leading models operating around the country today. These models are either completely planned water reuse systems or combined with indirect water recycling (indirect potable reuse). While they differ in scale, treatment intensity, integration, and cost, each has a clear place in Australia’s water future.

We’ve provided at least one successful example for each model, with a quick summary of essential pump tech, insights, and links.

1. Stormwater Harvesting & Reuse

Best for: Specific community rainwater/stormwater reuse (for parks, sports fields, precincts, and flood-prone suburbs); augmenting non-potable supplies

How it works: This water reuse model focuses water reuse efforts entirely on seasonal rains and floods. Depending on a system’s size and chosen scope, this can service a few selected areas or an entire community, regardless of stormwater source.

Stormwater is captured from hard surfaces and pit-and-drainage systems, then collected at a central treatment area. After treatment (e.g., natural wetlands filtration, artificial filtration, UV, chlorination), the treated water is pumped to various specific locations or applications. (Examples: industrial washdowns, irrigation of public parks or bushland, firefighting, or toilet flushing.) This not only eases the demand for potable water and augments non-potable supplies but also helps manage local flood risks.

Typical Pump Tech:

- Stormwater collection frequently uses either pumps with larger solids passage or screening ahead of pumps, to cope with debris loads

- Customised submersible pumps to lift raw stormwater with debris and variable flows

- Centrifugal pumps for filtration loops and backwashing

- Metering/diaphragm pumps for disinfectant dosing (e.g., chlorine)

- Level-controlled boosters to serve irrigation zones with steady pressure

- Axial flow propeller pumps for minor dewatering in small flood-prone spots

Example: Angus Creek Stormwater Harvesting (Rooty Hill, NSW)

Stormwater captured from Angus Creek and the adjacent sports precinct (Sportspark) is treated and reused for irrigation across public spaces. Reported annual yields can be as much as 200 megalitres a year , enough to materially offset irrigation demands.

Key insights:

- Combine local flood mitigation with water supply (two wins from one investment).

- Seasonal variability demands smart controls and storage buffers.

- Public benefits (greener parks during drought) build community support.

Similar Cases:

See the Warrnambool Roof Water Harvesting Project (Warrnambool, VIC) and the Fitzgibbon Chase housing development in Brisbane (QLD).

2. Onsite Reuse

“Onsite reuse” means you collect and treat wastewater close to the source, then reuse it within the same site. By keeping the whole recycling loop within your site, you gain tighter control over your water usage and avoid the extra cost of pumping reused water elsewhere.

2.1 Building-Scale Onsite Reuse

Best for: Small residential complexes, large private estates, apartments, hotels, campus buildings, high-water-use facilities

How it works: Office buildings or housing complexes tend to focus on recycling greywater and rainwater. This is because more toxic wastewater (e.g., sewage, floodwaters) requires more space for a longer treatment process.

At this scale, Membrane Bioreactor (MBR) systems are appropriate. It’s a wastewater treatment technology that combines biological treatment (like activated sludge) with membrane filtration. It eliminates the need for the usual large settling tanks (which are used in large raw water and wastewater treatment plants) and requires less property space to operate.

For instance, you can collect greywater from your property’s showers, basins, and laundries and treat it within the building or housing complex itself. Then you cycle the water back to pipes within the same property for non-potable onsite needs, such as flushing toilets or garden watering.

Typical Pump Tech:

- Compact submersible pumps in balance tanks; booster sets for toilet risers

- Diaphragm/metering pumps for disinfection (e.g., UV plus residual chlorine)

- Including macerators or fine screening, where solids might enter the treatment plant (depending on connection points)

- Backwash-capable centrifugals, smaller peristaltic or diaphragm pumps are essential for cleaning media filters/membrane clearing in MBRs

- MBR systems with submerged membranes primarily use permeate pumps or suction/blowers for air scouring

- However, some MBR membrane filtration configurations may use vacuum pumps to maintain negative pressure across ultrafiltration membranes

Example: One Central Park (Chippendale, NSW)

This mixed-use high-rise development has two towers, each one featuring outer vertical green walls and horizontal planter boxes (integrated into the facades). These green walls and planters total about 1,200 m² and are irrigated using recycled water (on-site treated wastewater), plus local rainwater, stormwater runoff, and groundwater mixed in as needed.

One Central Park has its own internal water recycling plant designed for this purpose. The entire system also includes overflow collection to help keep most of the water in the loop and meet irrigation demands.

Key insights:

- Onsite reuse for urban residential complexes or commercial buildings works best in new builds, where plumbing can be designed for dual collection.

- Retrofit is possible but often constrained by space and riser access.

- System design is highly specific and fit-to-purpose.

- Maintenance and monitoring are crucial for safety and health compliance.

Similar Case:

See the Inkerman Oasis multi-storey residential community in St Kilda, Melbourne.

2.2 Industrial Wastewater Onsite Reuse

Best for: Remote industrial sites, factories, processing plants, data centres, refineries, and business parks

How it works: Industrial operations tend to generate massive amounts of wastewater with levels of toxicity not found in office buildings or small residential communities. Thus, a system for industrial onsite wastewater collection, treatment, and redistribution of treated water is always customised according to a specific industry and a factory’s requirements and limitations.

A factory or plant’s onsite water reuse system can be based on a Membrane Bioreactor (MBR) or a more conventional wastewater treatment process. Once treated, you can safely pump recycled water to specific processes on your site that don’t need potable water. Examples include: cooling towers, mining washdowns, general cleaning, or irrigation.

Recycling that wastewater and reusing it within the same industrial or commercial facility is a good way of decreasing reliance on utility companies, slashing discharge, and minimising impact on the natural environment.

Typical Pump Tech

- Centrifugal pumps with VFDs (Variable Frequency Drives) to match variable process loads

- For highly viscous industrial sludges, however, hopper-fed progressive cavity pumps (PCPs) or peristaltic pumps are used

- Macerator pumps to protect downstream membranes/filters from fibres and solids

- Vacuum systems and air release valves to maintain stable hydraulics across complex pipe racks

- Vacuum pumps for dewatering sludge or process residues (if applicable)

- Metering pumps for scale inhibitors, anti-foam, corrosion control, and disinfectants

- Rotary lobe or roots blowers to provide the necessary air for any microbial treatment or equalisation tanks (for sites using biological treatment for high organic load wastewater)

Example: Visy Pulp & Paper Kraft Mill (Tumut, NSW)

Visy’s Tumut Kraft Mill in New South Wales is a large integrated paper mill producing kraft liner & recycled paper. Built in 2001 and later expanded, the site’s size is about 1,100 hectares and produces over 680,000 tonnes of kraft paper annually for domestic and export markets.

The mill upholds a tightly controlled water management and minimal liquid effluent discharge policy. It draws and uses raw water from the Tumut River for all its production processes, then gathers the wastewater or effluent it generates. They treat wastewater onsite through their own biological treatment system and reuse it for their cooling systems and for irrigation of farmland (located around the mill itself). Even other sludges and process residuals are reused as fertilisers or soil amendments.

They also capture and reuse or store rainwater runoff. In winter, they store any surplus treated or processed water in an onsite dam (to be used in the summer). As a result, no effluent leaves the site. This is important, as the Visy mill is located about 500 metres away from Tumut River, which runs along the northern and eastern boundary of the site. (Some of the mill’s irrigation and water management areas extend toward it.)

The facility also couples water reuse with energy reuse. It operates a cogeneration plant using biomass waste (bark, sawmill residues, etc.). The “black liquor” from the pulping process supplies part of its electricity and steam needs. This integrated approach reduces dependency on both external water and energy inputs.

Key insights:

- Closed-loop reuse of all process water onsite minimises freshwater extraction and discharge, achieving “near-zero” liquid discharge (ZLD).

- Advanced biological and mechanical filtration allows continuous reuse while meeting strict environmental standards.

- Integrated energy and water systems support treatment processes, improving overall efficiency.

- Industrial water reuse can align with both cost savings and environmental compliance.

Similar Cases:

See the Carlton & United Yatala Brewery (QLD) and BlueScope Steel’s Port Kembla Steelworks (NSW).

3. Centralised System With Indirect Potable Reuse (IPR)

Best for: Metro/regional drought resilience; serving multiple users; leveraging existing dams/aquifers

How it works: This is the most common large-scale water reuse model in Australia. While some may claim this is a “closed-loop” planned water reuse system, it still combines some passive use of the natural water cycle for potable or drinking water.

The collection and treatment of wastewater and/or sewage is done at a central facility. A portion of the wastewater is treated to a safety level acceptable for non-potable applications, then rerouted to specific users. These users are often power plants, factories, or agricultural farms.

Meanwhile, a significant portion of the wastewater is treated and purified for release to dams, aquifers, or natural rivers. The treated water mixes with existing raw water in those bodies and gets exposed to nature’s water cycle (i.e., evaporation, condensation, precipitation, collection) before finding its way back into a separate raw water treatment plant. That plant produces fresh potable water, which it then pumps into the tap water supply grid that distributes it to end users. This aspect of the system is called indirect potable reuse or IPR.

Typical Pump Tech:

- High-duty centrifugal and vertical turbine pumps for bulk transfer between plants and storage areas

- Metering pumps for precise chemical dosing (pH control, anti-scalants, disinfectants)

- Side channel blowers and rotary lobe or roots blowers for aeration in biological stages upstream of advanced treatment

- Main and redundant high-pressure positive displacement pumps with Variable Frequency Drives (VFDs) automatically control and drive reverse osmosis (RO) reliably

- Supervisory Control and Data Acquisition (SCADA)-integrated boosters to maintain pressure across long pipelines and elevation changes

Example: Western Corridor Recycled Water Scheme (SE Queensland)

Built during the 2006-2008 drought at the cost of AUD 2.5 billion, the Western Corridor Recycled Water Scheme is a large‑scale operation that collects wastewater from Brisbane, Ipswich, and other nearby catchments.

Wastewater processing is centralised in advanced treatment plants located at Bundamba, Luggage Point, and Gibson Island. They employ microfiltration, reverse osmosis (RO), and UV/advanced oxidation. The scheme has a technical capacity of up to ~232 ML/day.

The distribution network can deliver recycled water to local irrigation networks, the Swanbank Power Station, Tarong Power Station, and Tarong North Power Station (outside the region). They are also tied to the larger South East Queensland (SEQ) Water Grid. It supports the wider community in SEQ through indirect potable reuse potential and by reducing demand on potable water supplies.

When the water at Wivenhoe Dam goes down to critical levels, the system can supplement it with purified recycled water. Wivenhoe connects to the South East Queensland Water Grid and is a source of raw water for the wider SE Queensland community. Recycled water eventually filters back into the area’s drinking water supply.

The entire scheme is currently held in care-and-maintenance mode and is operated when required under SEQ contingency rules.

Key insights:

- Large-scale wastewater treatment and reuse using this process: microfiltration → RO → UV/advanced oxidation → targeted industrial users and raw water reservoir (Wivenhoe).

- Success hinges on multi-barrier treatment, robust pumping, and strong governance.

- Centralised indirect potable reuse (IPR) provides regional drought insurance without retrofitting every street.

- Operates in “care and maintenance” mode until triggered by lower reservoir levels; helps balance cost with readiness.

- Repurposed existing infrastructure where possible.

Similar Cases:

See Perth’s Groundwater Replenishment Scheme involving the Beenyup Advanced Water Recycling Plant.

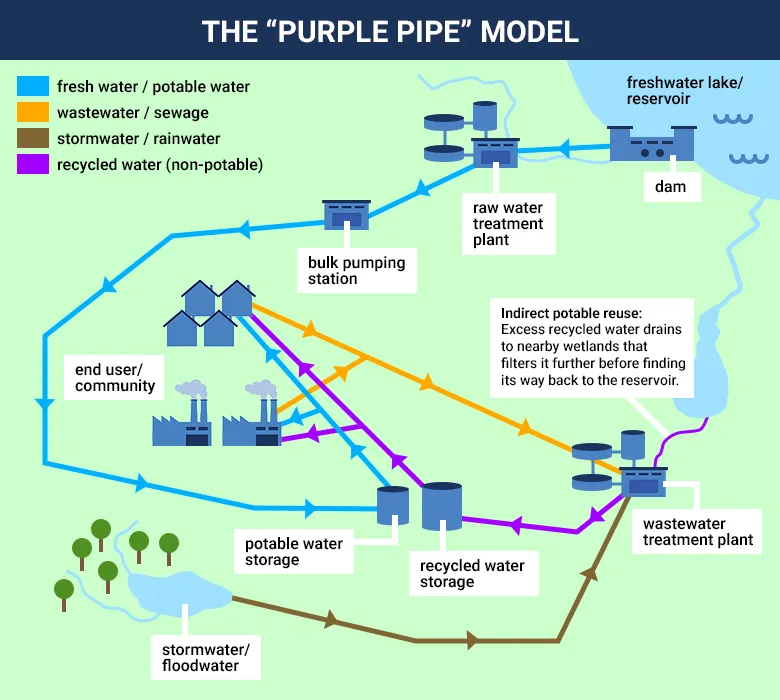

4. Dual Reticulation (“Purple Pipe”)

Dual reticulation supplies homes and public spaces with two networks: potable and recycled (non-potable). By having two separate water supply systems, you can cut down the unnecessary use of potable water across multiple users in a network.

The potable water network is what supplies water to kitchens, bathroom faucets, and shower heads, and any other spot that comes in direct human contact. In Australia, this is commonly provided by the water utility company servicing the entire region (i.e., centralised supply).

Meanwhile, the separate recycled water network goes to toilets, selected laundry uses, gardens, and sports fields. Typically, this separate piping system is colored purple or lilac, making safety and maintenance operations for each network easier to manage.

4.1 Decentralised Purple Pipe (Onsite Reuse)

Best for: Small communities, new estate centres, remote sites, tourist parks, university/health precincts

How it works: In this version of dual reticulation, you collect wastewater generated within the same property or community and treat it within that area. Then you cycle it back through a separate purple pipe network that services multiple users within that community. It avoids sending the wastewater to a centralised regional treatment plant and redistribution scheme that services other areas.

The purpose of this model is to “decentralise” or reduce a small community’s reliance on the larger network grid for water supplies and water recycling.

Typical Pump Tech:

- Progressive cavity or submersible pumps to move sludges or solids-laden flows gently

- Depending on airflow, pressure, and turndown requirements, aerobic treatment basins may require side channel blowers (lower flow/higher pressure niches) or rotary lobe/roots blowers (larger aeration needs).

- Metering pumps for coagulants, nutrients, or disinfectants

- Duty/standby transfer pumps across compact tanks and modules for resilience

Example: Currumbin Ecovillage (Gold Coast, QLD)

Located in the Gold Coast hinterland’s Currumbin Valley, Currumbin Ecovillage is a 147-lot residential community that operates completely off the mains sewer network. Wastewater is collected, treated, and reused onsite. The system uses a combination of membrane filtration and UV disinfection to produce Class A+ recycled water (state-level classification). This water goes through a purple pipe network for non-potable uses such as toilet flushing, garden irrigation, and landscape maintenance.

The facility includes multiple storage tanks and a one-megalitre buffer to ensure a reliable supply. Complementing this are other sustainable water systems, such as rainwater harvesting for potable use and bio-retention swales and ponds for stormwater management.

Key insights:

- The model suits off-grid or fringe developments with limited mains sewer access.

- Ideal for where land use planning and sustainability goals align early; design planning with mandatory plumbing standards ensures system success.

- Storage buffers provide supply reliability and operational flexibility.

- Integrating rainwater and stormwater management enhances overall water efficiency.

- Offset high upfront costs with lower long-term operational and environmental costs.

Similar case:

See Googong township (NSW) and its purple pipe recycled water system.

4.2 Integrated Dual Reticulation

Best for: A series of adjacent new townships and large “greenfield” estates

How it works: This integrated version of the scheme connects multiple suburbs or developments through a single treatment and distribution network.

Wastewater is collected and treated at a centralised regional plant. Then the recycled water is distributed through a separate non-potable “purple pipe” network that services all households, offices, commercial, and industrial operations across different suburbs or a large area.

In terms of scope and depth, this model is the largest and most intricate of the water reuse systems. And while it is best for “greenfield” areas (new or still undergoing development), some older communities may have the budget and infrastructure flexibility to become part of such a scheme.

Typical Pump Tech:

- Essentially the same pump tech as decentralised purple-pipe neighbourhoods, except with larger models for heavier duties

- High-reliability duty/standby pump stations at the treatment plant outlet

- Zone boosters and pressure-reducing valves (PRVs) to maintain pressure and avoid nuisance trips

- Network monitoring to detect cross-connection risks and ensure service levels

Example: Rouse Hill Water Resource Recovery Facility (Sydney, NSW)

The Rouse Hill Water Resource Recovery Facility (WRRF) is one of Australia’s largest integrated dual reticulation residential water recycling schemes. Located in Sydney’s North West, the facility acts as the central treatment plant for wastewater from suburbs like Rouse Hill, Stanhope Gardens, Glenwood, Kellyville, Kellyville Ridge, Parklea, Acacia Gardens, Beaumont Hills, Quakers Hill, The Ponds, and Castle Hill.

The plant handles about 24 million litres per day of wastewater and supplies up to 2 billion litres of recycled water a year to around 32,000 properties. It operates under multiple licences (e.g., from the NSW EPA) and must continuously meet Australian Guidelines for Water Recycling.

Water is treated through a multi-step process: primary screening and grit removal, followed by secondary biological treatment (activated sludge / bioreactors + intermittently decanted aerated lagoons), then tertiary treatment (flocculation, clarification, filtration, plus disinfection using ultraviolet light and chlorine). The treated recycled water then goes to homes and businesses for non-drinking purposes (toilet flushing, garden watering, washing cars, etc.) through a separate dual-reticulation network (purple pipes) so it doesn’t mix with the drinking-water supply.

Unlike Indirect Potable Reuse (IPR) models that have significant environmental discharge, the WRRF releases minimal excess treated water (if any) to nearby wetlands.

Key insights:

- The sooner you design dual reticulation into an area, the cheaper and cleaner it is.

- Clear public communications and purple-pipe conventions reduce risk and build trust.

- Handover to Council or water utility companies with mature O&M plans keeps standards high.

Similar case:

See the Mawson Lakes Recycled Water Scheme for select areas of Salisbury City (SA).

Main Takeaways

- Stormwater collection is often the cheaper water reuse model to start implementing. But it eventually comes with significant technical and regulatory constraints (e.g., catchment contamination, variable quality, approvals, treatment for human contact) that can complicate implementation. Stormwater harvesting needs appropriate treatment for its intended use.

- Use dual reticulation in new developments.

- In older or existing suburbs, pursue precinct-specific projects (e.g., for parks, campuses, industrial estates) and continue relying on regional indirect potable reuse (IPR) to keep water reuse efficient and cost-effective.

- For smaller councils or townships, implement water reuse in stages or multiple models, as needed: start with council-owned parks, add industrial customers, integrate new estates with dual reticulation, and keep options open for regional augmentation later.

- Expect challenges around upfront pipework costs, public perception, long-term maintenance, and compliance. These soften with strong stakeholder engagement, smart funding (grants, developer contributions), and by timing installations alongside other civil works (road upgrades, renewals).

Make your future water resilience a reality now

With the right wastewater recycling technology and know-how, your community or facility can be ready for whatever the climate throws at it.

Whether you’re upgrading an existing treatment plant, establishing a precinct-scale reuse scheme, or master-planning dual reticulation in a new development, our team at Flo-Max can help you. We have the Australian pump engineering expertise, the resources, and the network of water recycling experts you need. We can custom-build the pump technology to keep quality on spec and your water moving where it’s needed.

Contact us and see how we can start your future water resilience today.