If you’re a non-technical asset or project manager trying to learn more about vertical turbine pumps, this article is for you.

Obtain the fundamental knowledge you need to communicate effectively with your pump engineers, comprehend the complexities of turbine pump installation, and appreciate how its benefits can outweigh costs.

What Is A Vertical Turbine Pump (VTP)?

When pump engineers talk of “turbine pumps,” they are often referring to the vertical turbine pump (VTP).

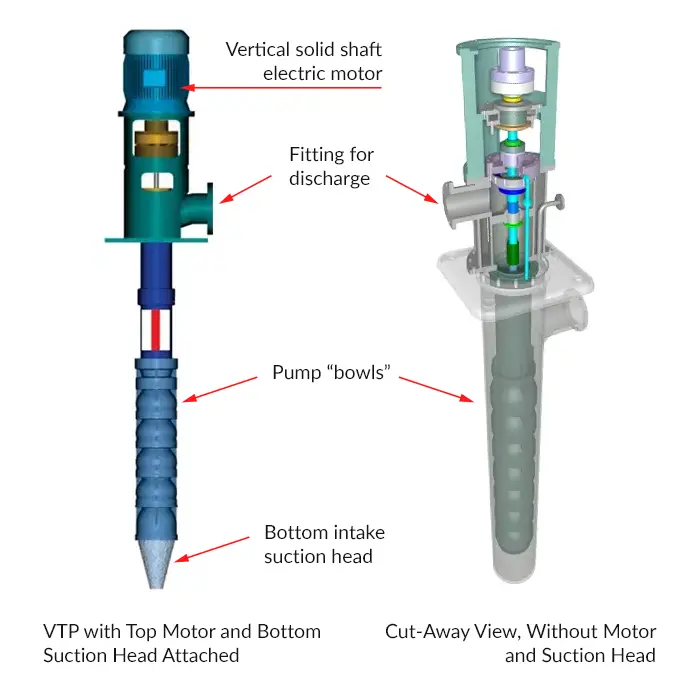

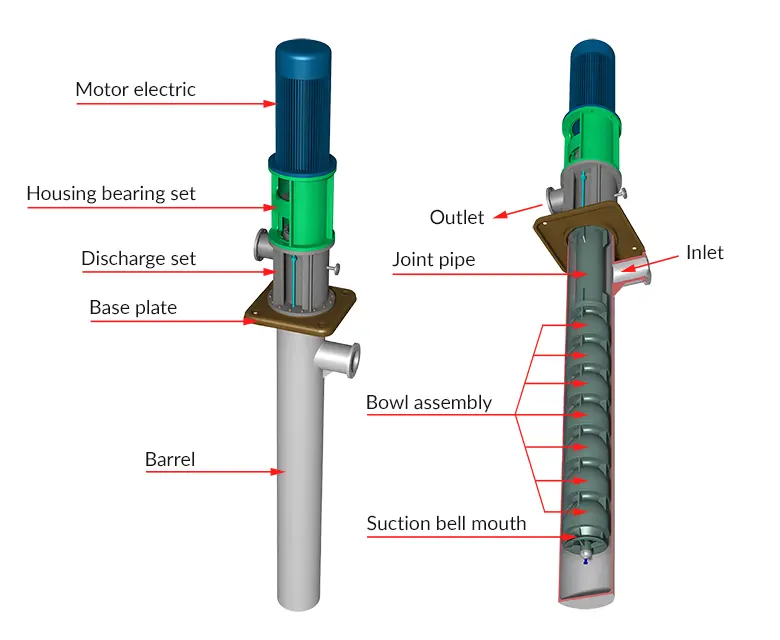

A VTP is a type of centrifugal pump that can efficiently transport large amounts of liquid from deep underground sources. These pumps are built vertically, with the motor above ground and a column shaft driving a series of impellers below the surface.

They’re powerful enough to handle high-head, large volumes and high pressure applications for various types of fluids. Thus, they have many industrial uses.

Where Do Turbine Pumps Work Best?

Vertical turbine pumps or VTPs work best in high-head, high-lift applications with stable flow rates.

Definition of Terms

- “High head applications” – This means operations that involve high discharge pressure. The pump should generate enough pressure or energy to push liquid a long way or against strong resistance.

- “High lift applications” – These are operations where you must pump fluid up a high vertical distance. VTPs are well suited to both high head and high lift requirements.

- Metres of Head (m) – This is the unit of measurement pump engineers use to express how much “head” or energy a pump can impart to each unit weight of the fluid. (Note that this is independent of fluid type.) In simpler terms, it specifies how far up the pump must push the fluid. This is why it is expressed in metres. When pump duties are said to include a high lift and high head, this is usually above 100 m, sometimes exceeding 300–500 m for multi-stage turbine pumps.

- Flow rate – This is the volume or amount of fluid a pump moves. A high flow rate means a pump can move a large volume of fluid. (Pumps can move large volumes of liquid even if head and pressure are low.)

- Stable flow rate – This means the liquid flow doesn’t change rapidly or frequently. The pump can run without requiring constant fast adjustments (i.e., throttle up or down suddenly). VTPs do best in these stable conditions and get worn more quickly if flow rates vary greatly and often.

Best Industrial Applications of Vertical Turbine Pumps

While vertical turbine pumps (VTPs) were originally invented to move water, they are now applied to a wider range of systems:

- Municipal and Utility Water Systems – Cities and regional councils often rely on VTPs to draw raw water from rivers, dams, and aquifers into treatment facilities. As high-flow water pumps, their multi-stage configuration allows them to generate the high pressures needed to push water through treatment systems and long distribution networks efficiently.

- Mining and Resource Projects – In mining, turbine pumps are often used for dewatering, process water handling, and tailings transfer. Their rugged build and ability to handle varying water levels make them perfect for the harsh, fluctuating conditions typical of mine sites across Australia.

- Power Generation and Cooling Systems – Large-scale energy facilities use turbine pumps for cooling-water intake and circulation. These pumps can run continuously, supplying massive volumes of water to maintain temperature stability in turbines, condensers, and other equipment.

- Industrial Process and Chemical Plants – In manufacturing and chemical processing, turbine pumps handle liquids of various densities, viscosities, and levels of abrasiveness or corrosiveness. When built with durable materials and multi-stage capabilities, these pumps can move challenging materials such as saltwater, dilute sulphuric acid, gypsum slurry, and more.

- Irrigation and Agriculture – For large irrigation systems that draw from bores or rivers, turbine pumps deliver the consistent pressure and high flow irrigation rates needed to feed distribution lines over long distances. Their vertical design also keeps the motor safely above ground, reducing maintenance downtime and flood risk.

Most Common Turbine Pump Variants

There are also different types of vertical turbine pumps. Here’s a table showing the most common ones.

| VTP Type | Pump Duties | Most Common Industries | Typical Fluids |

|---|---|---|---|

| Radial-Flow Vertical Turbine Pump | High head, lower to moderate flow | Municipal water supply & irrigation Mining (dewatering, process water transfer) Oil & gas (API 610 VS1/VS6 types) Geothermal plants |

Water, condensate, hydrocarbons, light oils, brine, deep-well pumping |

| Mixed-Flow Vertical Turbine Pump | Medium head, high flow | Power plants (circulating + cooling water) Petrochemical & refineries (cooling loops) Large HVAC industrial cooling towers Desalination pre-treatment |

Cooling water, seawater, intake water, recirculation flows |

| Axial-Flow Vertical Pump | Extremely high flow, very low head | Cooling water in thermal/nuclear power plants Flood control & stormwater stations Irrigation districts Large-scale mining tailings ponds |

Massive water circulation, low head lifting (1–15 m), floodwater |

| Vertical Multistage Turbine for Deep Well | Very high head via many stages | Groundwater extraction Mine dewatering shafts Agricultural bores Industrial deep wells |

Bore water, ground aquifers, mine inflows |

| API 610 Vertical Turbine (VS1/VS6) | Specially-engineered for high head | Oil & gas refineries Petrochemical plants LNG terminals |

Light hydrocarbons, condensate, amine solutions, LPG-like fluids |

| Vertical Sump / Cantilever Turbine Pumps | Fluids with solids or mixed media | Mining process plants Chemical plants |

Light slurries, corrosive sumps, process waste streams |

The Advantages & Benefits of Using Turbine Pumps

VTPs offer a unique set of advantages that make them the default choice for the applications mentioned above.

Technical Advantages

- High Flow Capacity

- Can handle very large volumes of water or other fluids, from tens to thousands of litres per second.

- Ideal for mining, municipal water supply, irrigation, and industrial applications.

- High Head / Multistage Capability

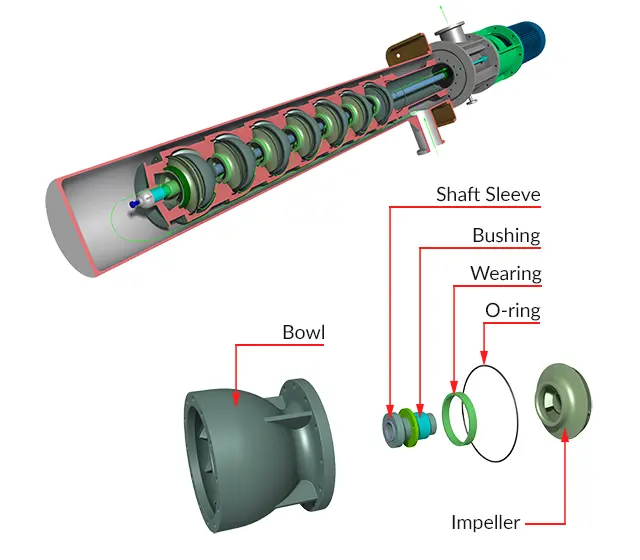

- Multi-stage impellers allow lifting water from deep wells or pits, reaching high heads (up to 500 m or more).

- Supports applications requiring significant vertical lift without increasing impeller diameter.

- Customisable Materials & Construction

- Available in cast iron, bronze, stainless steel, duplex alloys, and other corrosion/abrasion-resistant materials.

- Can handle fresh water, salt water, hot water, or chemically aggressive fluids.

- Durability and Long Service Life

- Robust design with bearings, shafts, and bowl assemblies engineered for decades of heavy-duty operation.

- Can be overhauled in situ, reducing downtime and extending lifespan.

- Ability to Operate in Harsh Conditions

- Performs reliably in dirty water, seawater, high-temperature, or cold-climate environments.

- Water-lubricated or oil-lubricated bearings can be specified depending on the duty and environment.

- Flexible Suction Arrangements

- Can pump from deep wells, wet pits, reservoirs, or other below-ground sources.

- Bowl and impeller designs can accommodate variable water levels.

- Efficiency at Designed Duty Points

- Multi-stage design ensures energy-efficient operation when sized for the intended flow and head.

- High efficiency reduces operational energy costs in continuous operations.

- Low Maintenance Downtime with Proper Servicing

- Bearings, column bearings, and impellers are designed for easy maintenance and replacement.

- Flo-Max or other experienced suppliers can provide preventive maintenance and quick repairs.

- Adaptability to Industry Applications

- Suitable for municipal water, wastewater, irrigation, mining dewatering, seawater cooling, industrial process water, and offshore facilities.

- Can be custom-engineered to fit specific site constraints or fluid requirements.

Operational Benefits

Even without understanding pump curves or hydraulics, it’s easy to appreciate how these turbine pumps’ technical advantages translate to benefits. With VTPs, your operations gain reliability, longevity, and adaptability. You also safeguard safety and reduce operational risks for your employees.

Here are a few industry-specific examples of how turbine pumps can benefit operations.

Example Industry Applications

| Industry | How turbine pumps help | Specific operational benefits |

|---|---|---|

| Mining | Move water for dewatering, process operations, or tailings management | Reliable operation, high flow, suited for harsh conditions |

| Irrigation & Agriculture | Deliver water from wells or reservoirs to crops | Handles variable water levels, long-lasting under heavy use |

| Municipal Water Supply & Wastewater | Pump drinking water or wastewater efficiently | Minimises downtime, ensures continuous supply to communities |

| Industrial Facilities | Cooling water, process water, fire water | Durable materials handle hot/cold water and corrosive fluids with ease |

| Offshore & Marine Applications | Seawater supply, process or cooling water | Reduced maintenance work and risks in marine settings; materials resistant to corrosion; pumps designed for long-term reliability |

Technical Requirements & Limitations

Vertical turbine pumps’ technical requirements limit where you can apply them. Be aware that these requirements also mean higher initial costs and a more complex installation compared to other pump types.

Here’s why:

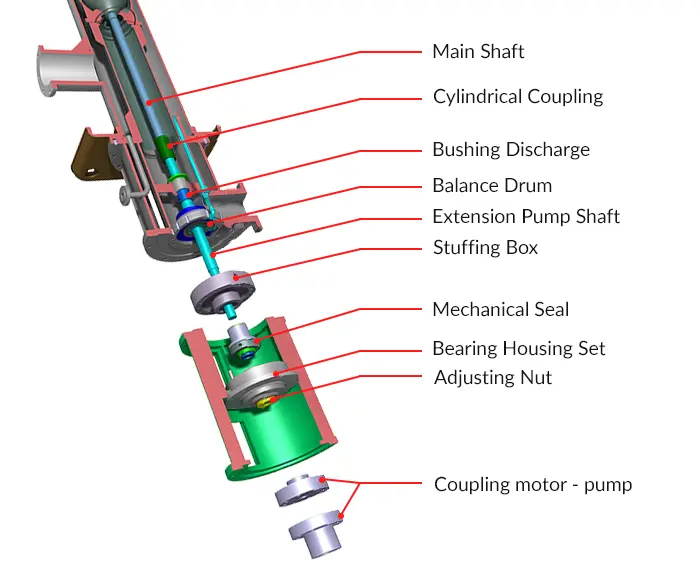

1. Required vertical mount

- VTPs require preparation of a wet well or pit, structural supports, and often specialised lifting equipment for installation and maintenance.

- Gravity alignment keeps the pump shaft and bearings straight.

- The long column shaft stays stable and well-lubricated.

- Lubrication (i.e., open line shaft water lubrication or enclosed oil-lubricated columns) works properly only in a vertical orientation.

- Other aspects of the pump design work best or exclusively for vertical mounting.

- The pump bowl assembly (impellers, diffuser bowls, suction bell) sits below the water surface.

- The column pipe and line shaft rise vertically up to the motor or right-angle drive at the surface.

- The motor or right-angle gear drive sits on top of the discharge head.

- Any deviation from a vertical mount by a few degrees will require additional modifications.

- These are called angled or inclined mixed-flow or turbine pumps (used for drainage, irrigation canals, or cooling water intakes).

- Typically installed at 15–60° angles to reduce shaft length or fit into an embankment.

- But they’re still mostly vertical in structure and use similar hydraulic components (bowl, impellers, line shaft).

2. Customisation according to fluid

These pumps can handle almost any liquid — including seawater, hydrocarbons, chemicals, and process fluids — provided that the fluid’s properties and chemistry are matched with the right pump materials, bearings, and lubrication systems.

Here are a few examples of how turbine pumps are best configured according to fluids handled:

Turbine Pump Customisation Based On Fluid Type

| Application | Fluid Type | Customisation |

|---|---|---|

| Municipal / Utilities | Potable water, raw water, seawater, wastewater | Bronze or stainless components resist corrosion; often oil-lubricated shafts. |

| Irrigation / Agriculture | Irrigation water, recycled water | May use open line shaft for water lubrication. |

| Mining | Slurries, deep pit dewatering wastewater, tailings water | Heavy-duty construction, wear-resistant alloys, hardened impellers. |

| Oil & Gas / Petrochemical | Hydrocarbons, condensate, light oils | API 610 vertical turbine (VS1, VS6 types) variants as high flow fuel pumps; often use enclosed shafts and special seals. |

| Power Generation | Cooling water, geothermal brine, condensate, hot well service | Stainless or duplex steel used for high temperature-resistant VTPs |

| Food / Beverage | Hot process water, brine | Sanitary materials and designs where required. |

| Desalination / Marine | Seawater, brine | Duplex or super-duplex stainless steels, or titanium for anti-corrosion. |

When building custom pumps, manufacturers and engineers don’t only consider the frequency and intensity of pump duties or the distance and height the liquid must move. They must also factor in the intended fluid’s characteristics, such as:

- Viscosity (affects efficiency and required torque)

- Density / specific gravity (affects head and power required)

- Temperature (affects expansion and materials)

- Solids content (affects wear)

- Corrosiveness (affects materials and lubrication choice)

- Lubricity (affects shaft bearings — especially if water-lubricated)

For example, if the fluid isn’t self-lubricating (like oils), you may need an enclosed shaft and external lubrication. If it’s corrosive or saline, you’d specify alloys like 316/904L stainless, duplex, or even titanium.

3. Sensitivity to NPSH (and cavitation issues)

NPSH stands for Net Positive Suction Head. Your pump engineers may define it as “the measure of how much pressure is available at the pump suction, above the vapour pressure of the liquid.”

But in plain English, NPSH is the measure of how much pressure your pump has at its inlet to avoid cavitation.

Cavitation is a problem that can occur in vertical turbine pumps. When the pressure of the liquid gets too low, it forms ‘cavities’ or vapour bubbles within the liquid. And when those bubbles form and collapse within the pumps, they damage impellers and reduce performance.

Why is NPSH a limitation for VTPs?

When in operation, vertical turbine pumps often have long columns that transport liquids at high flow rates (e.g., moving water from deep wells). These conditions naturally make it harder for them to maintain sufficient pressure (i.e., low NPSH) at the “eye” of the first-stage impeller.

If and when cavitation occurs often, vibration increases, and the rate of wear and tear of the impeller and bowl accelerate. Over time, you’ll notice your turbine pump losing efficiency.

Calculating for safety

To compensate, vertical turbine pumps must be built based on careful calculations of NPSH and safety margins that are specific to your situation.

Your hydraulics and pump engineers will be measuring and calculating details such as:

- height of fluid above the pump

- atmospheric pressure

- fluid temperature

- friction losses in the suction line

- vapour pressure of the liquid

- NPSHa – how much pressure your operating environment and liquid contribute

- NPSHr – the minimum pressure needed at the pump inlet so the pump won’t cavitate at a given flow rate.

- Safety margins

These measurements and calculations will help engineers build a pumping system that ensures your NPSHa never falls below the minimum pressure your turbine pump requires (NPSHa ≥ NPSHr + safety margin).

Added safety features

Because of their sensitivity to NPSH and varying flow rates, the majority of vertical turbine pump-based systems are built with these safety features:

- Multi-stage by design. “Multi-stage” turbine pumps have more than one impeller (or “bowl assembly”) stacked vertically along the same shaft. Each impeller adds energy (or “head”) to the fluid as it passes upward through the pump. The cumulative effect of several impellers in series allows a VTP to generate very high discharge pressures, even when the individual impellers are relatively small.

- Low suction pressure and variable flow tolerance options. These features help counter or prevent rare low-pressure events or sudden changes in flow:

- Low-NPSH impeller – This is a specially-modified first impeller that reduces the pressure drop that occurs as liquid enters the pump.

- Inducer – A smaller axial-flow impeller can be mounted ahead of the first-stage impeller that “pre-boosts” incoming fluid (raising suction pressure before reaching the main impeller).

- Suction bell – This is the open “bell mouth” at the very bottom of a VTP bowl assembly that is made with a larger diameter. It helps lower fluid entry velocity.

- Soft starters – Electrical motor starters can ramp up voltage gradually during startup. These do not adjust speed once the pump is already running.

- Variable Frequency Drives (VFDs) – Electrical control devices that gradually adjust the pump motor speed, softening transitions across a wider flow range. These can manage both pump startup and running speed.

- Surge tanks or accumulators – Pressure vessels installed in the suction or discharge line to absorb shock or supply short bursts of flow. They act as buffers that dampen pressure spikes or compensate for momentary loss in suction flow. These are external system components and are not part of the pump itself.

When Vertical Turbine Pumps Aren’t the Ideal Choice

1. Highly variable or very low flows

Here are a few example scenarios where flow demand changes quickly or constantly:

- variable-production chemical processes

- fast batch dosing systems

- systems with sudden valve openings/closings

- surge-prone pipelines

- wastewater systems with highly unpredictable inflow

- mining circuits with fluctuating slurry densities/volumes

If your operation frequently cycles through stops and starts or rapid throttling, your VTPs will not last long. Those conditions only increase vibration at thrust bearings, stress the shaft, and create cavitation that accelerates wear on impellers. Your pump engineers will recommend that you use other models instead, such as axial-flow pumps.

2. Highly problematic liquids

Generally speaking, VTPs’ efficiency and durability are compromised by these fluids:

- Highly viscous fluids (e.g., heavy crude oil, syrup, sludge)

- Slurries with large abrasive solids (impellers quickly wear down unless they’re specially coated or hardened)

- Fluids with strong gas entrainment or variable density (may cause cavitation or head instability).

For such cases, engineers often switch to using submersible slurry pumps (for abrasive mixtures) or positive displacement pumps (for thick or slow-moving fluids), such as progressive cavity pumps, gear pumps, or screw pumps.

3. Horizontal mount

In theory, VTPs can be adapted to operate at semi-diagonal to semi-horizontal orientations. But it’s seldom practical. Engineers would have to overcome major issues in shaft deflection, bearing load, and lubrication.

At that point, it’s more efficient to use a different pump type (e.g., horizontal multistage centrifugal pump) which can achieve similar head and flow ranges without mechanical penalties.

Tips for Turbine Pumps Preventive Maintenance & Service

With proactive planning, managers can extend pump life significantly, minimise operational disruptions, and ensure their turbine pumps perform reliably for decades.

- Start with monitoring wear points that naturally degrade over time. Plan routine inspections of line-shaft bearings, bowl and impeller clearances, mechanical seals (if fitted), and shaft alignment. If your pumps are handling abrasive water, seawater, or variable water levels, inspections should be more frequent.

- Track performance indicators such as vibration, energy consumption, and changes in flow or discharge pressure. Even small deviations often signal early-stage cavitation, bearing wear, or shaft deflection, allowing you to intervene long before reliability drops.

- Prepare for the practical realities of servicing a VTP, from an annual budget for repairs and overtime for employees to contracts with third-party services and logistics. Major overhauls typically require cranes or lifting beams, clear vertical access, and scheduled shutdown windows to safely remove the column and bowl assemblies.

- Remember to factor in the need for repeat applications of protective coatings, upgrading metallurgy, or periodic refurbishment (rather than budgeting only for complete overhauls from unexpected failures).

Optimise Your Operations With Our Custom Turbine Pump Solutions

If you’re considering upgrading your operations with new vertical turbine pumps, call us for help. We offer full pump engineering services, from designing and custom-building to full repairs and maintenance work.

As an Australian pump OEM with over two decades of experience, we can custom-build the turbine pumps you need from our engineering facility in Sydney. Our team of engineers will fit them to your fluid properties, duty points, and site conditions.

More importantly, we also offer on-site pump servicing and off-site pump repairs or overhauls, so you don’t need to orient a different service team to do the job.

Still unsure about which high-head pump solution to use? Contact us today to get the engineering advice you need.