An Australian gold mining facility recently needed Flo-Max’s help with turbine pump repair. The challenge with this particular case was that the equipment was over a decade old and manufactured by a different pump engineering company.

Regular refurbishing of large industrial pumps

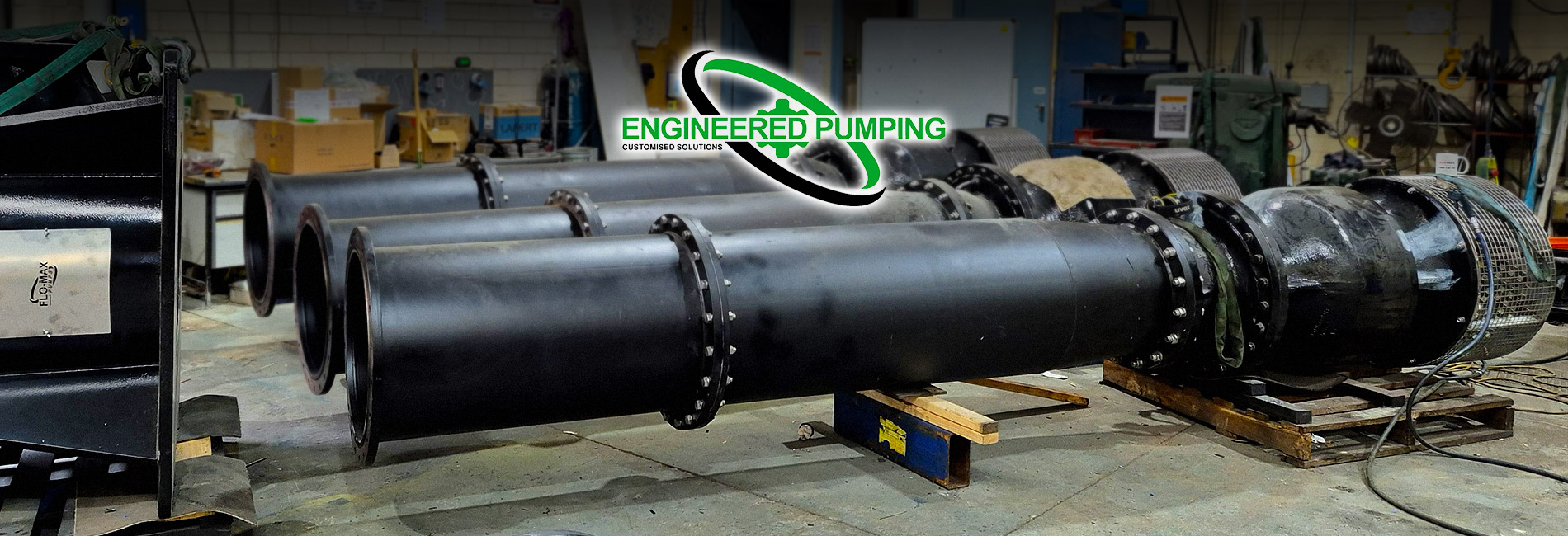

We all know even the most heavy duty pump will not last forever and needs to be regularly serviced. Our client in this case study used this 28-inch two-stage turbine pump to manage the conveyance of non-saline groundwater or mine wastewater from their site. After more than a decade of constant usage, the pump was due for refurbishment.

The turbine pump had previously undergone maintenance checks and occasional repairs with either the original manufacturer or other pump engineering companies. But this time, none of them were available to work on the entire turbine pump (with the motor, thrust blocks, pipe column and bowl assembly).

Since we regularly service all kinds of pumping equipment, we got the job. Our facilities, toolset and most importantly our experienced personnel means we are able to carry out any extensive turbine pump repair of this kind.

Servicing and overhaul of old turbine pump

When we disassembled the gold mine’s old dewatering turbine pump, we found that many parts had completely rusted or worn down. So we set about cleaning, repairing, replacing or repainting them as needed.

Professional pump maintenance you can rely on

We are engineers, not sales people, so we go beyond selling pump technology. Whether you’re looking for new pumps to augment your operations or revive your old equipment, we’ll make sure you get the right equipment in the right condition. After decades in the business, we also have an extensive network of partners, if we ever need additional capacity or if a pump would benefit from specialised tooling.

We understand how critical pump repairs are to keeping your mining operations safe and cost-effective. Whether you need repairs for wastewater turbine pumps, progressive cavity pump upgrades for moving drilling mud or side channel blower pumps to control airflow, we have the equipment and expertise you need. Contact our engineers for the professional pump maintenance your business deserves.