Reliable Industrial Side Channel Blowers – Selected, designed, and supported by experienced Australian engineers

Your Side Channel Blower Specialists in Australia

When requiring side channel blowers, you’ve come to the right place. We are your airflow control experts. Because we know air pump technology like no one else in Australia. Since 2001, we’ve been dedicated to supplying clients like you with safe and reliable air pumps, even for the most delicate or hazardous of operations. We understand how critical it is for your chosen side channel blower model to meet the highest standards of safety and reliability.

Air Control Expertise

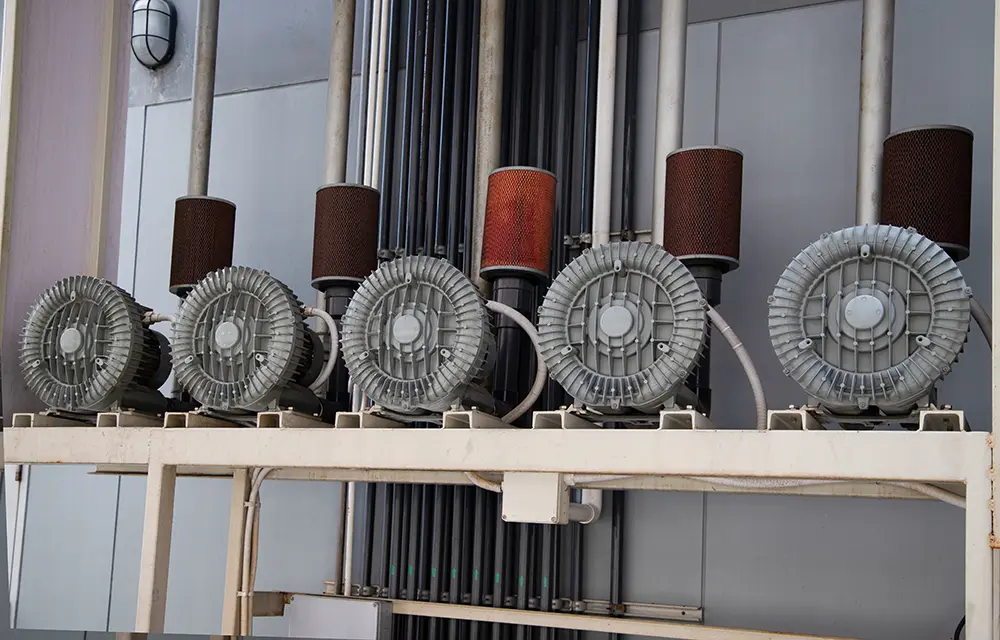

Side channel blowers (regenerative blowers) are an essential component of many industrial processes and safety systems. Naturally, custom-fit side channel blowers are an integral part of our pump engineering expertise. Wherever gases, liquids, or suspended particles need aeration, you will find our blower products.

Our specialist engineers can help you choose the right side channel blower for your application and make your operations run at maximum efficiency. If your processes have special requirements or are performed under more hazardous conditions, we can assist you with a bespoke solution.

Comprehensive Service

We are a team of engineers, not salespeople. When you partner with us, you acquire more than just pump technology. You get our dedicated technical support and documentation. We steer the entire process, from installation and validation to operations launch and beyond. Our team will be there to offer you guidance and support for maintenance and repairs. Your side channel blowers will integrate flawlessly with your existing systems.

Enhanced Efficiency

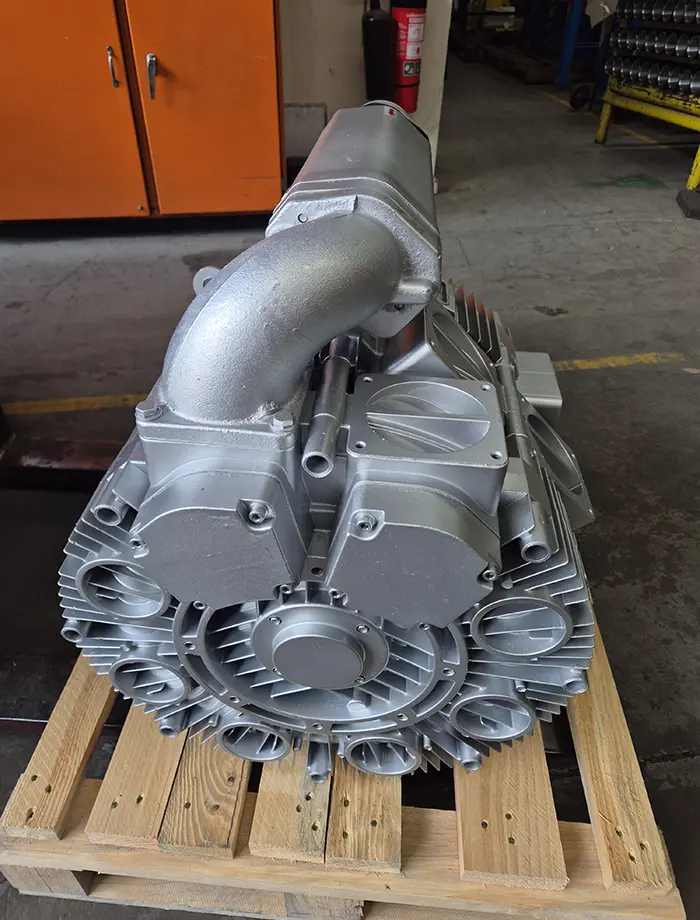

Whether you’re engaged in food processing or wastewater and biogases, we have a blower ideal for your application. You can rely on our equipment to provide the delivery you require, ensuring maximum energy efficiency. Our range of models is the widest on the market. Higher pressures can now be achieved with lobe blowers.

Explore our range of side channel blowers today and experience the Flo-Max difference for yourself.

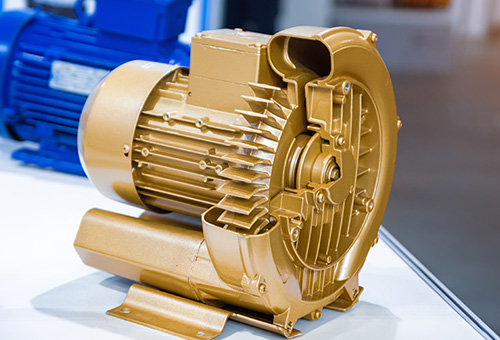

Flo-Max Heavy Duty Side Channel Blowers

Side channel air blowers are a quieter, lower-maintenance alternative to positive displacement lobe blowers. They provide oil-less and contactless compression of gases. The latest generation of blowers offers continuous discharge pressures of up to 1 bar [14.5 psi] and flows of as high as 2,500 cubic metres per hour. Our low-noise blower solutions can help reduce the cost of acoustic enclosures required to silence noisy lobe blowers.

General Features

- Wide range of models to ensure the most efficient selection (e.g., single or double stage; single to triple impellers).

- Different electric motors available, configured in direct, belt, or VSD drive.

- Lower generated noise levels

- Oil-free and contactless manipulation of airflow

- Durable and reliable; little maintenance required

Side Channel Blower Applications

Side channel blowers are widely used in industries that require clean, oil‑free, and low‑maintenance air or gas movement. Their ability to deliver steady airflow at moderate pressures makes them suitable for a broad range of industrial processes.

Typical side channel blower applications include:

- Water supply treatment, aeration, and wastewater processing

- Swimming pool filter backwash

- Aquaculture – Fish and shellfish farming

- Large-scale construction and carpentry

- Automatic car wash

- Dental suction systems

- Methane gas extraction

- Soil and groundwater remediation

- Gas emissions monitoring

- Chemical processing

- Dehydration or conditioning of farming produce

- Particle conveyance in food processing – powders, grains, granules, and suspensions

- Carpet cleaning trucks

- Sludge tankers

Available Side Channel Blower Models

Explore our range of side channel blower models designed for industrial performance in Australia. From versatile IEC-compliant motor-powered side channel air blowers to ATEX-rated versions for hazardous environments, our selection delivers efficient, oil-free airflow across a wide spectrum of side channel blower applications.

Electric Motor-Driven Blowers

Our blowers are powered by IEC (International Electrotechnical Commission)-compliant electric motors. Choose from lower cost IE1 standard efficiency, or higher efficiency IE2 and IE3 motors in various blower configurations (i.e., 1, 2, or 3 stage versions).

- Available in single-stage, double-stage, and three-stage versions

- Blower design and electric motor for low noise levels

- IEC-compliant electric motors (IE2, IE3) help minimise overall energy consumption

- Clean oil-free operation and minimal maintenance

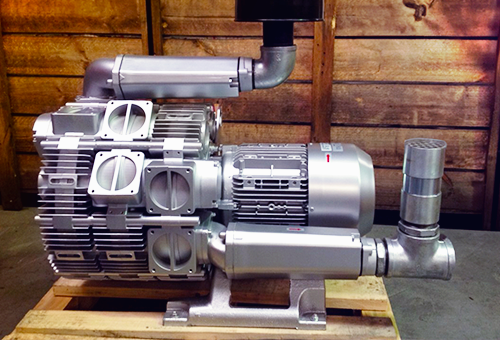

ATEX Motor-Powered Blowers

For hazardous requirements, we have side channel blowers with upgraded motors. These blowers have ATEX-compliant motors (compliant with the European Atmosphere Explosible Directive),

- Heavy-duty series

- Available in single-stage, double-stage, and one to three impeller versions

- ATEX-compliant motors for hazardous working environments

- Lower running temperatures

Available variations and configurations

Whichever side channel blower models you choose, we can further systemize the package to suit your particular operation.

- Single stage, [1 impeller]. Ideal for achieving flow rates up to 1000 m³/h, at low pressure/ vacuum levels reaching +/-400 mbar.

- Double stage, [2 impellers in series]. Best used in situations that need limited flow demand, with pressure/ vacuum levels reaching +/-600 mbar.

- Double stage, [2 impellers in parallel]. Double impellers allow for large quantities of suction air up to 1900+ m³/h, with pressure/ vacuum levels reaching +/-400 mbar.

- Three-stage, [3 impellers in series]. with pressure/ vacuum levels reaching +/1000 mbar.

- Enhanced safety features. Our blowers are IEC and ATEX compliant. However, if you’re seeking equipment for more demanding or extreme environments, our engineers can further customise your side channel blowers to your specifications. For instance:

- Internal combustion or PTO motor drive.

- Dust ignition-proofing (extra protection or insulation from particle ingress)

- Flameproofing (e.g., built-in flame paths, special inner bearing covers, motor housing to contain internal explosions)

- Non-sparking motors (no sparks or hot surfaces during operation)

- Waterproofing (for applications involving water management, e.g., aquaculture and wastewater remediation)

Typical Performance Ranges and Uses

Here are a few common examples of side channel blower configurations and the pressure and flow requirements they address.

| Configuration | Typical Flow Range | Typical Pressure / Vacuum | Common Uses |

|---|---|---|---|

| Single Stage | Up to ~1,000 m³/h | Up to ±400 mbar | Light aeration, small conveying systems |

| Double Stage | Up to ~1,900 m³/h | Up to ±600 mbar | Water treatment, vacuum lifting |

| Three Stage | Up to ~2,500 m³/h | Up to ±1,000 mbar | Higher‑pressure industrial processes |

However, when choosing a side channel blower model and configuration, you’ll still need a pump engineer’s experience with how these ranges apply to different duties and situations. The pump’s actual performance will depend on your operating conditions and selected motor specifications.

Our team of pump engineers is here to provide you with the expertise you need. We’ll ensure that your specially-configured side channel blower units will work smoothly with the rest of your system and deliver the air control you require.

Frequently Asked Questions

What are side channel blowers best used for?

Side channel blowers are best suited for applications requiring clean, oil‑free air or gas at moderate pressure or vacuum levels, such as aeration, conveying, and vacuum handling. To see examples in more detail, see our overview of blower applications.

How do I know how many stages I need?

An experienced airflow pump engineer can calculate and advise you on this. Choosing the correct side channel blower model depends on the pressure or vacuum your process demands. Single‑stage units suit lower pressures, while multi‑stage blowers are used when higher pressure levels are required.

When is an ATEX side channel blower required?

ATEX‑rated side channel blowers are required when operating in potentially explosive atmospheres or hazardous environments. Selecting the correct certification is a critical safety consideration and should be part of the overall blower selection process.

Raise Your Airflow Control and Efficiency

Looking to take your airflow control and safety processes to the next level? Work with us here at Flo-Max. Our experienced pump engineers are ready to help you raise efficiency. See how our other airflow pumps can also help improve your operations. Get in touch with us for advice, comprehensive technical details, and a competitive quote.