Australia’s bushfire seasons are becoming more severe, driven by climate change. While the destruction of land and property is devastating, an often-overlooked consequence is drinking water contamination. We have spent years building pumps for water treatment for various clients in Australia and we’ve helped them deal with water contamination issues after bushfires. In this article, we’ll share what we know of the best strategies and water treatment pumps to use for this problem.

If you work for local council or manage a water utility, this is exactly the starting information you need. But consult us as soon as possible, for bushfire water contamination is an urgent matter. The sooner we help you adapt and choose the best pumps to strengthen your water treatment processes, the safer your community’s water supply will be.

How Bushfires Impact Water Quality

Much of Australia’s tap water comes from carefully managed rain catchment areas, which include natural rivers, lakes, and other reservoirs. Nearly all of these are located near bushfire-prone areas, which has far-reaching consequences for the safety of our drinking water.

Ash, sediment, and pollutants from bushfire-devastated areas can reach nearby water catchments via wind or heavy rains. Once contaminated, the raw water in these catchments abruptly changes.

Key Changes in Water Quality After Bushfire

- Increased turbidity: Excessive sediment from eroded bushfire-affected ground decreases the water’s clarity and changes its colour.

- Increased chemical toxicity: The immense heat of bushfires releases any heavy metals and chemicals present in both natural and urbanised environments. These include toxic substances such as arsenic, mercury, and other metals, as well as contaminants from burnt infrastructure, including plastics and treated wood.

- Increased carbon levels: Burnt vegetation and organic debris raise the level of dissolved organic carbon (DOC) in the water. These will react with standard water treatment disinfectants like chlorine and form harmful by-products.

- Increased temperature: After a major bushfire, any nearby bodies of water experience a temporary rise in temperatures higher than 25 degrees Celsius. Such temperatures encourage bacterial growth.

- Nutrient overload: The phosphorus and nitrogen from bushfire ash can promote algal blooms in water. These blooms harm aquatic ecosystems and produce toxins that affect water safety.

- Oxygen depletion: These can also trigger an increase in the breakdown of organic matter present in the water. In turn, this may deplete dissolved oxygen levels and kill fish and other aquatic life.

A catchment can take 5 to 20 years to naturally recover from bushfire contamination. Until then, raw water entering municipal treatment plants can overwhelm existing filtration and disinfection systems.

How to Mitigate the Effects of Bushfire Water Contamination

Preparation is key. To reduce bushfire impact and maintain safe drinking water standards, local councils and water utilities need to adopt the following preemptive measures:

- Establish better erosion control – Stabilise the soil structure of areas next to water catchments. Protecting and reinforcing natural river banks or lake shorelines (i.e., by riprap, silt fences, live trees or natural material cushioning) may be useful. But it is best complemented by extensive replanting and maintenance of wild vegetation in areas further off. These will act as a natural pre-filter whenever minor floods or rainwater runoff passes through.

- Enhance water quality monitoring – Upgrade the assessment process to measure additional key indicators of bushfire water contamination, such as a change in pH and alkalinity, an increase in turbidity, or a rise in dissolved metals, oxygen and carbon. These will entail the use of monitoring devices and periodic tests, which require vacuum pump-based detectors.

- Upgrade water treatment procedures – Repair old or damaged control lines or tracks. Local councils can install additional devices at the water catchment sites or access channels. They can also introduce more pump aerators and special units for pre-chlorination and dosing of activated carbon, potassium permanganate (KMnO4), and the appropriate coagulant or flocculant (e.g., aluminium sulphate). These can help further oxygenate, clarify and disinfect the raw water so that existing treatment plants can effectively filter and render it safe without getting compromised.

- Implement better staff training and public communications – Municipal employees must also be regularly trained to deal with water quality issues after bushfires, especially when managing pump systems and administering safe substance doses. Emergency coordination procedures and communication between local government, residents and other stakeholders must be clear and well-established.

Critical Pump Upgrades For Bushfire-Resilient Water Purification

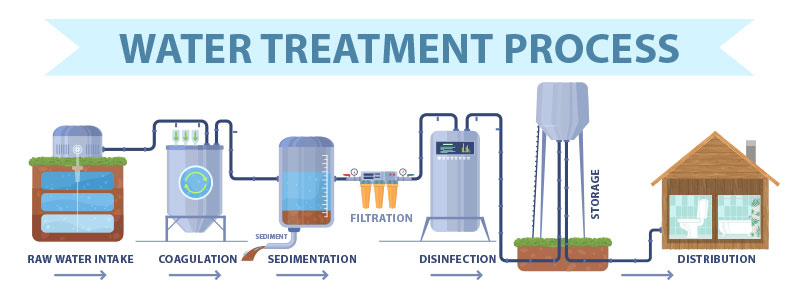

If you’re a local government manager tasked to mitigate the effects of future bushfires on your community’s water supply, the following pump technologies may need to be added or upgraded along key points in your existing water treatment process.

1. Redundant Aeration Units

Applicable Pumps: Side Channel Blowers, Rotary Vane Pumps, Diaphragm Pumps

Municipal councils and water treatment plants can add modular side channel blower-based aeration systems along various stages of water collection and purification. (Rotary vane or diaphragm pumps are also appropriate for this application.) These added units can scale up operations whenever drinking water quality is threatened after a bushfire.

High turbidity levels from sediment and ash require a robust pre-treatment method. Additional blowers at the water catchment and intake channels would be an advantage. By constantly blowing air into raw water, these pumps support beneficial microorganisms in breaking down organic matter. This agitation also controls algal blooms, reduces odour, and helps oxidise any heavy metal contaminants.

2. Additional Backwash Pumps and Enhanced Filtration Support

Applicable Pumps: Centrifugal, Vertical Turbine, Submersible Pumps, Side Channel Blowers

Backwash pumps are critical for de-clogging and cleaning filtration systems overwhelmed by sediment, ash, and organic debris post-bushfire. While centrifugal pumps dominate this application, other pumps like side channel blowers, vertical turbine pumps, submersible pumps and peristaltic or diaphragm pumps may also be used, depending on the design and location of the water treatment plant.

- Underground filtration flushing – When added into an underground filtering system, submersible pumps can ‘backwash’ or reverse water flow around filters to dislodge accumulated debris. This is especially important in conditions caused by bushfire runoff. Having extra backwashing pumps can keep various sand, granular activated carbon (GAC) and other media-based filtration systems more resilient to sudden changes in water turbidity.

- Surface filtration support – Increased contamination also strains surface filtration systems. Adding side channel blowers as extra backwash filtering pumps can effectively dislodge accumulated debris, ensuring the rest of the system can cope.

- Emergency sludge backwash support – In the worst post-bushfire conditions, raw water may become a highly variable liquid or sludge. Water treatment facilities will need extra diaphragm or peristaltic filter backwashing pumps they can switch on to help manage the influx of heavier debris or sediments.

3. Additional Flow Control and Chemical Dosing Units

Applicable Pumps: Vacuum Pumps, Metering Pumps

A typical water treatment plant already uses vacuum pumps and metering pumps to control water flow and the precise dosing of flocculants and other substances. However, installing more pumps like these will be necessary in managing future water contamination after bushfires. These additional units can be turned on or off whenever the need arises. Their location will depend on the location of the water source and the design of the existing municipal water treatment plant.

- Accurate dosing – Additional metering pumps can safely administer more coagulants, disinfectants and other chemicals anywhere along the initial stages of the water treatment process. These substances will accelerate sedimentation, neutralise pathogens and adjust the pH balance.

- Flow control – Extra vacuum pumps can also be installed between the flocculation, sedimentation and final filtration stages. These can help ensure a consistent water flow from one basin to the next.

Case Studies of Adaptation

Here are a couple of well-documented cases where additional pump technology and improved water treatment techniques were successful:

- Victoria’s 2009 Black Saturday Fires: Water authorities faced severe challenges in treating reservoirs heavily contaminated with ash and debris. Investments in additional aeration systems, often powered by side channel blowers, helped stabilize water quality and prevent algae outbreaks.

- 2020 Black Summer Fires in New South Wales: These fires highlighted the vulnerability of Sydney’s catchments. Increased turbidity and chemical contamination tested the limits of treatment systems. Facilities that incorporated enhanced aeration and backwashing techniques saw improved outcomes in maintaining drinking water standards.

Safeguard Your Water Quality Today

Climate change-driven bushfires present complex challenges for Australia’s water catchments. These require innovative approaches to ensure safe drinking water. The use of additional pump technologies in these innovations is critical.

We have the flexibility and experience to custom-build the cutting-edge pump solutions you need to handle post-bushfire water treatment. We’ll help you enhance your aeration, chemical dosing, filtration backwashing, and treated water monitoring with the right pumps. You can ensure your water treatment plant can effectively adapt to increased contamination levels, safeguarding drinking water quality and public health.

Contact us and explore how we can help make your water treatment processes more sustainable. Together, we can build resilient systems to meet tomorrow’s challenges.

Main References:

Jackson, Reed, et al. “The Influence of Recent Bushfires on Water Quality and the Operation of Water Purification Systems in Regional NSW | Scientific Reports.” Nature, Springer Nature, July 2024, doi:https://doi.org/10.1038/s41598-024-66884-3.

“Bushfires and Water Quality.” Water Quality Australia, Australian Government Initiative, https://www.waterquality.gov.au/issues/bushfires. Accessed 11 Feb. 2025.

“Water by Region.” Commonwealth Environmental Water Holder, Australian Government, https://www.dcceew.gov.au/cewh/water-region. Accessed 11 Feb. 2025.