As climate change leads to more prolonged and frequent droughts, wastewater reuse will become an increasingly important issue. This means water recycling pumps will play an increasingly important role in building up climate change resilience for Australia.

In this article, we’ll look at which sectors in the country have the best potential to scale up water recycling by the next decade – and what pump technologies can help fast-track that adaptation.

Why Increased Water Reuse is Crucial to Australia’s Future

As one of the driest inhabited continents on the planet, Australia stands as one of the countries with the most wastewater treatment and water reuse. Water conservation is always a national priority. Meanwhile, climate change will continue intensifying droughts and depleting natural water sources.

Thus, to safeguard future water supplies, more communities and large-scale industries in Australia must diversify their water sources. This means reducing reliance on groundwater and freshwater reserves and increasing the use of locally recycled wastewater and stormwater.

Priority Areas for Increased Water Recycling

With widespread political support, water reuse expansion efforts will likely follow this sequence.

1. Agriculture & Agribusiness (Immediate Priority)

Agriculture and agribusiness (including commercial forestry and fish farming) remain Australia’s largest water consumers, using 60–70% of the nation’s annual supply. While they depend heavily on freshwater for crop irrigation, livestock, and food production, they are also among the country’s leading sectors for water recycling. However, they have concentrated most of their recycling in drought-prone areas. With the right initiatives, there is significant potential to expand water reuse further across this entire sector. They are already better equipped to make that happen.

2. Heavy Industry (Next Priority)

Many processes in heavy industry already operate as systems semi-independent from the local water utility ‘grid.’ With government subsidies and the backing of investors, they can retool or expand their operations to rely more on reused water. They can have their own water recycling off-grid or connect to their local community water reclamation system.

Taken together, various heavy industries make up about 13% of the country’s total water consumption. The biggest of them are:

- Mining – Requires large amounts of water for ore processing, dust suppression, and mining waste management. Some mines already use recycled water, but reliance on freshwater is still dominant. Increased use of recycled water can help reduce the environmental impact of mining operations.

- Manufacturing – Industries like food processing, textiles, and chemical production can integrate recycled wastewater into operations to cut costs and improve sustainability. There is a high potential for water reuse in cooling, cleaning, and production processes.

- Construction & Property Development – Incorporating water recycling into commercial and residential developments ensures long-term water efficiency. Large office buildings and commercial centres can use recycled water for cooling, landscaping, and sanitation.

- Hospitality & Tourism – High water consumers (such as big hotels, resorts, and amusement theme parks) that can benefit from greywater recycling for non-drinking purposes.

3. Households – via Local Councils & Government Water Utilities (Long-Term)

For maximum impact, more Australian households should be directly connected to a local water recycling system.

Households are the country’s second-largest water users, accounting for around 10-13% of the nation’s annual consumption. Yet currently, most homes still aren’t connected to a closed-loop water recycling system—even for non-potable uses like garden irrigation, clothes washing, and toilet flushing.

Expanding wastewater recycling within local councils’ management of water treatment, distribution, drainage, sewage, and related infrastructure must be done thoughtfully, with strong support from the federal government and utility companies. The ultimate goal is to upgrade wastewater treatment facilities and extend recycled water distribution to all households.

Such an expansion would also benefit municipal drinking water systems, supplying offices, shops, restaurants, parks, and essential public services like toilets and drinking fountains.

Controlling the Water Recycling Chain

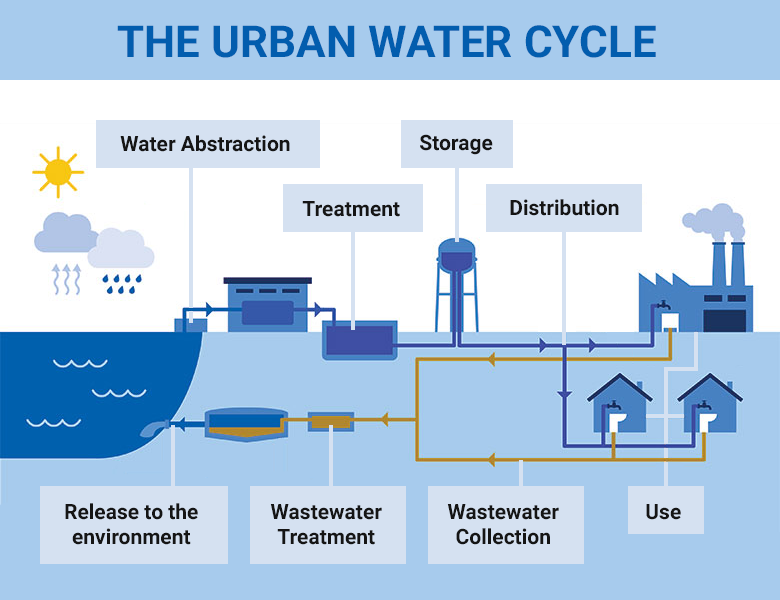

Scaling up water reuse requires direct control over the water recycling chain, everywhere. This means creating more carefully planned recycling systems, rather than falling back on “unplanned reuse.”

Unplanned Reuse

Most communities simply discharge their treated wastewater directly into the environment. There is no direct control over when and how nature cycles water back into catchments and reservoirs (e.g., rain), where we ultimately source our freshwater. Hence, this situation is considered “unplanned reuse.”

Example: Urban wastewater from households or industrial processes typically goes down the drain and collects in septic tanks or a sewage system. The wastewater is then diverted into a treatment plant and discharged into a nearby river or sea.

Planned Reuse

By contrast, planned reuse is a “closed loop” system that gives more control over the water recycling chain. Stormwater and wastewater are collected and diverted into one or more applications. Depending on the safety level required, this ‘dirty water’ is subjected to appropriate levels of treatment and purification before use. With more advanced systems with water recycling pumps throughout Australia, we can even optimise the number of times we cycle back to recollect, re-treat, and reuse the water, before safely discharging it into the environment.

Example: Blackwater from households and retail businesses in an urban farming-friendly suburb is diverted into a modified municipal treatment and distribution facility. Stormwater is also collected.

All wastewater is treated to produce recycled water in various safety classifications. Some of it is safe for direct contact uses, such as laundering clothes, flushing toilets, and watering home gardens. Some of it is used in agricultural irrigation and industrial washdowns. The rest is released into a raw water reservoir or catchment, where the environment will filter it further and mix it with rainwater.

Eventually, that water from the reservoir is piped back into the community. It goes into a separate treatment plant (different from the recycling facility) before getting distributed as safe, potable water. (Potable water and recycled water come through separate pipe systems.)

General Strategies For Scaling Up Water Reuse

- Bolster existing practices: Australia already has a strong foundation for water reuse, particularly in non-potable applications like landscape irrigation. Key cities should continue being leaders in implementing and expanding recycled water systems.

- Invest in recycling technology: Maintain and upgrade pump technology and recycling facilities. Invest in advanced water treatment technologies, including membrane filtration and ultraviolet disinfection, to improve the quality of recycled water and open up possibilities for more diverse applications. Implement dual plumbing systems in new developments to deliver recycled water for toilet flushing.

- Commit to climate change-responsive policies: Further development and enforcement of clear water reuse guidelines at the federal and state levels are essential to ensure quality standards. Provide financial incentives for communities, industries, and businesses adopting water reuse practices. Fostering partnerships between water utilities, government agencies, research institutions, and community groups will facilitate knowledge sharing and implemention of water reuse strategies.

- Public perception: Addressing public concerns about the safety of recycled water is crucial for widespread adoption. This can be achieved through transparent communication and education campaigns highlighting the rigorous treatment processes involved.

Examples of Water Reuse

Agricultural

Centralise community wastewater treatment and use for irrigation.

On-site Reuse

- Reuse light wastewater from a home or building for non-potable purposes within the same location.

- Create on-site wastewater treatment and water reuse “closed loop” systems for heavy industrial sites (e.g., mining), especially in remote areas near protected bushland or waterways.

Industrial Operations

Designate various safety grades of recycled wastewater to the appropriate application. For example:

- Class A – safe for direct human contact

- Class B – industrial washdowns

- Class C – no human contact allowed

Potable Water

- Indirect reuse – Treat wastewater before releasing it into a lake or river

- Direct reuse – Advanced water recycling; direct reintroduction to the drinking supply system

Stormwater

Channel floods to central sewage treatment; replenish bushland, farmland, or natural reservoirs.

Essential Water Recycling Pumps in Australia

Water recycling depends on high-performance, customised pumps that effectively move, treat, and purify wastewater and stormwater. They are essential to ensuring your recycling operations meet Australia’s strict safety standards while remaining cost-effective for large-scale use.

Here are a few commonly used water recycling pumps in Australia and their functions.

1. Large-Scale Water Movement – Centrifugal & Submersible Pumps

Centrifugal pumps (above-ground or fully submerged) are essential in wastewater treatment and recycling, efficiently transporting water and sludge between treatment stages.

How They Help:

- Above-Ground Centrifugal Pumps: Move large volumes of treated and untreated water efficiently in municipal and industrial recycling systems. They maintain steady pressure in filtration, distribution, and discharge processes with minimal maintenance.

- Submersible Centrifugal Pumps: Operate fully submerged in wastewater, making them ideal for raw sewage, stormwater, and sludge transport systems. They handle high-solids wastewater without clogging and eliminate the risk of suction-related cavitation.

By selecting the right type of centrifugal pump for each stage, treatment plants improve efficiency and reliability.

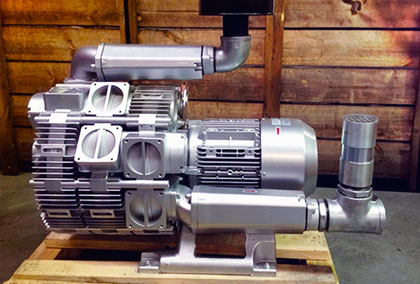

2. Aeration & Biological Treatment – Side Channel Blowers

One of the biggest challenges in water recycling is breaking down organic waste and contaminants. This is where side channel blowers come into play.

How They Help:

- Side channel blowers inject air into wastewater, supporting aerobic bacteria that break down organic pollutants.

- They prevent anaerobic conditions that lead to foul odours and inefficient treatment.

- These pumps are energy-efficient, making them ideal for long-term, continuous aeration.

3. Grinding Solids – Macerator Pumps

Macerator pumps break down solids in wastewater before pumping, preventing blockages and ensuring smoother treatment processes. These pumps are available in various designs, including centrifugal, diaphragm, and rotary lobe models.

How They Help:

- Centrifugal macerator pumps grind and move wastewater efficiently in high-flow applications.

- Diaphragm macerator pumps offer low-flow, high-viscosity grinding solutions.

- Rotary lobe macerator pumps grind and transfer sludge in industrial and food-processing wastewater systems.

By preventing large solids from clogging downstream equipment, macerator pumps improve efficiency and reduce maintenance needs in water recycling and wastewater treatment.

4. Handling High-Solids Wastewater – Progressive Cavity Pumps

Some types of water recycling deal with extremely contaminated liquids, such as industrial wastewater, sewage, muddy floodwater, or post-bushfire runoff.

Progressive cavity pumps excel in moving thick sludges that other pumps struggle with.

Key Benefits:

- Can handle highly variable, high-viscosity fluids with suspended solids.

- Provide gentle, low-shear pumping to prevent breaking down biological treatment agents.

- Function as macerator pumps as well, with modifications.

- Requires less maintenance than other pumps used for sludge transport.

5. Precision Flow Control & Chemical Processing – Vacuum & Metering Pumps

Vacuum pumps and metering pumps play a crucial role in controlling water distribution and dosing treatment chemicals.

Vacuum Pumps Help By:

- Maintaining consistent flow through filtration and disinfection systems, despite differences in elevation or number of divisions.

- Assisting in the removal of air pockets that can disrupt water treatment processes.

Metering Pumps Are Used For:

- Chlorination and UV treatment – Ensuring that recycled water is disinfected properly.

- pH balancing and coagulation – Preventing harmful chemical imbalances in treated water; dewatering sludges by injecting special polymers to start flocculation

6. Chemical Dosing & Sludge Handling – Diaphragm Pumps

Diaphragm pumps play a crucial role in metering chemicals and handling sludge with high accuracy and reliability.

How They Help:

- Ensure precise dosing of disinfectants, coagulants, and pH-balancing agents.

- Deliver pressure and transfer liquids from one treatment stage to another.

- Handle abrasive and corrosive fluids without damage.

- Provide leak-free operation, preventing contamination in water recycling processes.

Their ability to handle aggressive chemicals and difficult media makes them essential in advanced treatment facilities. Such facilities need to move liquid material along several stages, from collection points to treatment units, which diaphragm pumps do efficiently.

Build Up Future Water Resilience Now

With the right wastewater recycling technology and know-how, you can be ready for any future level of water scarcity.

Whether you’re upgrading an existing wastewater treatment plant or designing an intricate new water reuse system, we have the expertise and products to help. We provide customised water recycling pumps across Australia. We have the expertise to optimise your system for efficiency and sustainability.

Contact us now and see how our pump solutions can enhance your water recycling efforts and support future water resilience today.